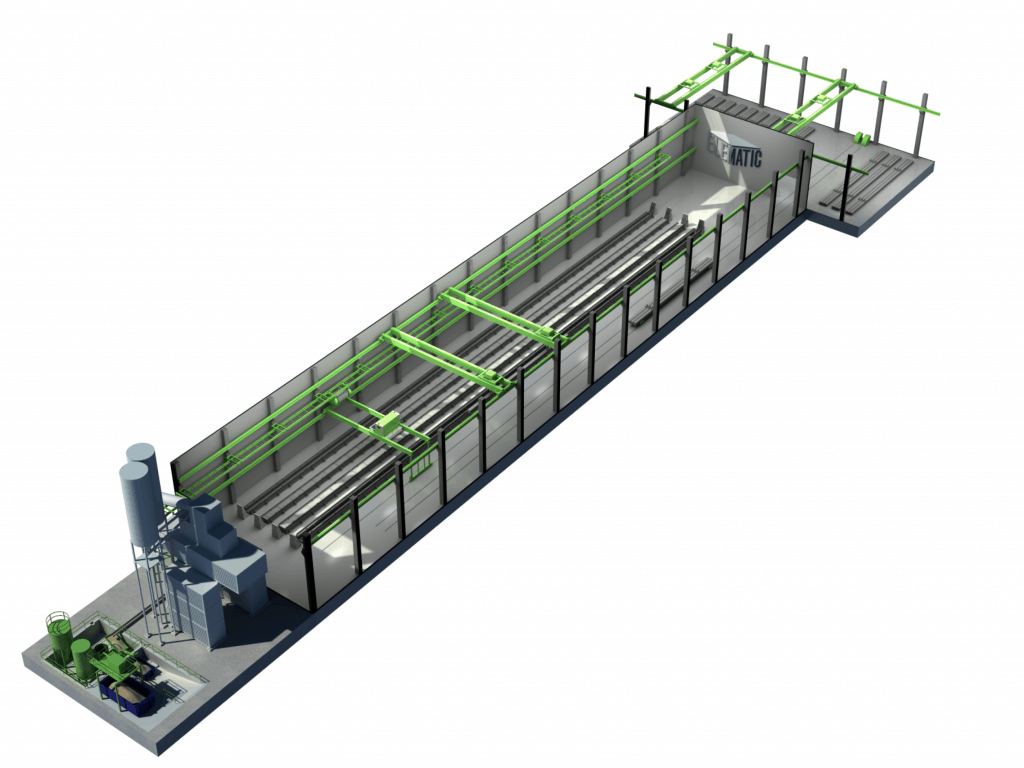

Combined hollow core and frame line

The Elematic combined hollow core and frame line offers a highly productive way to manufacture high quality composite slabs, hollow core slabs, TT-slabs, beams and columns with one production line. The line offers a high capacity utilization rate with wider product portfolio.

The combined hollow core and frame line covers the entire process from concrete batching to storage yard management. The line needs an area of 3,000 – 5,000 m2 for production, and the total land area required for the operation is around 10,000 m2.

Combined hollow core and frame line*

| Theoretical capacity | Hollow core slab 576 m2/day |

|---|---|

| Beams and columns 10-30 m3/day | |

| Production area | 3000-5000 m2 |

| Land area | 10 000 m2 |

| No. of beds | 4+2 |

| *All figures are estimates |

The combined hollow core and frame line features a compact layout for a wide product portfolio in the same production facilities. The regular set-up of the line includes six production lines out of which 4 are suitable for hollow core production and two for beams and columns, however, the lines are always designed case-by-case. The layout depends on production capacity requirements for the products.

Curing is speeded up with an integrated heating system installed on the casting beds. Heating on the line is based on hot water circulation.

PROCESS DESCRIPTIONS

Hollow core slab production takes place in 10 functional steps:

- Batching and mixing

- Concrete transportation

- Concrete distribution

- Bed preparation

- Pre-stressing

- Casting

- Slab modifying

- Curing

- Cutting

- Storing

The process starts with bed preparation. First, the bed is cleaned and oiled after which the prestressing strands are pulled. The strands are then pre-stressed. The casting machine is then lifted onto the bed and filled with concrete. The fresh slab is then modified with markings and openings, and then covered with a tarpaulin to maintain the optimal curing conditions. After curing, the slabs are cut to length according to the production plan. The cut slabs are lifted from the bed and moved to storage.

Beam and column production takes place in 10 functional steps:

- Batching and mixing

- Concrete transportation

- Mold preparation

- Reinforcement and furnishing

- Prestressing

- Casting and compaction

- Curing

- Demolding

- Mold cleaning and oiling

- Storing

The process starts with reinforcing and furnishing the beam and column mold. The reinforcement is placed in the casting mold. After that, the molds are cast with a casting machine called frame caster P7.

The beams and columns are cured on the molds typically 6 – 18 hours and then removed from the mold. The ready-made beams and columns are then transported to the stockyard with a transport wagon E9-1200w and the molds are cleaned and oiled for next casting.

SAMPLE PLANT CHARACTERISTICS

- Production crew: 10-15 persons in two shifts

- Concrete production: Modern Elematic B&M plant

- Concrete conveying: Automatic Elematic shuttle system

- Production lines: Served by wagons

- Stripping and hoisting: Handled by bridge cranes

- Change of molding: 4-8 hours by 4 men depending on molds

- Casting: Adjustable bucket, the level of casting is from 0.45 m to 2.7 m

- Hollow-core slabs: Max. 5 beds/working day

- TT-slabs: Max. 1 bed/working day

- HI- and I beams: Depending on the number of molds available

- Primary columns and beams: Max. 1 mold line/working day

SAFETY

All machines on the combined hollow core and frame line meet EC Machine Directive requirements. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Parts and services

Do you have questions? Contact us!

or