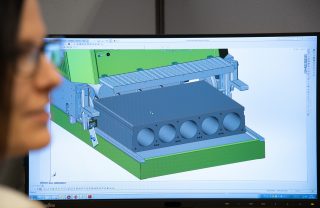

Saw E9

The Elematic Saw E9 is designed to automatically cut pre-stressed precast slabs, such as hollow core slabs, massive slabs, piles and T-beams, up to 500 mm thick. It can cut slabs at any angle: crosswise or longitudinally, and at any angle between.

Download a brochure

Saw E9-500 2022

| Width | 1670 mm |

|---|---|

| Height | 2560 mm |

| Length | 5670 mm |

| Weight without drums | 7500 kg |

| Saw transfer speed, stepless | 0-0.67 m/s |

| Water flow and pressure at saw min | 40 l/min @ 2 bar |

| Slab dimensions | |

| Width | max 1250 mm |

| Height | max 500 mm |

| Cutting blade diameter | 800-1350 mm |

The Elematic Saw E9 is a good solution for a precast factory where automated cross, longitudinal, and diagonal cutting is needed. Thanks to the low frame, the saw can also be easily adapted to existing facilities which have height limitations.

The machine is equipped with an on-board computer, a touch screen and a radio remote control. The touch screen displays machine data and it enables the operator to import slab data, adjust settings and access machine manuals directly from the machine.

New features in 2022 model:

- Dust reduction (HEPA 13)

- New blade movement and drive mechanisms for easier maintenance

- Simpler and more reliable mechanisms

- Reduced height: can fit in lower production halls

- Updated control system with an intuitive user interface and improved cutting control and programs

OPERATION

The Elematic Saw E9 is fully electric driven. It is equipped with intelligent cutting speed control and stepless control of the machine’s forward/reverse speeds. The control system stores the running hours for the machine and for the blade.

The Saw E9 features four saved product-specific cutting programs to ensure slab cutting is consistent. The blade height is programmable and it can be programmed to bypass for example protruding lifting loops, etc. – to maintain a smooth production flow.

The machine includes integrated water sprays to clean the slab surface after cutting, which ensures excellent bonding of topping at the construction site.

AUTOMATIC OPERATION

For automatic operation, the casting program is downloaded from the production planning software (Plant Control FloorMES machine control module) and the machine is placed at the starting position of the casting program. The saw then cuts the slab according to the program, completely automatically. The Saw E9 is also equipped with ultrasonic sensors to detect obstacles in the way and will stop cutting if necessary. A Wi-Fi connection is included

NOTE! In order to use the automatic features , the machine requires a FloorMES machine control module (see below). When the Modifier is equipped with a FloorMES machine control module it is compatible with BIM design systems.

.

SEMI-AUTOMATIC MODE

In semi-automatic mode, the saw is operated manually via remote control. There is a laser line which indicates the position of the blade to help position the saw accurately.

The cutting cycle is performed automatically according to the selected cutting program. After cutting, an electric brake quickly stops the blade for increased safety. The slab can be cut at any angle: crosswise or longitudinally, and at any angle in between: Crosswise (90°), diagonal (0°-180°) and longitudinal (0° or 180°) cuts.

DUST REMOVAL SYSTEM

The Saw E9 is equipped with a dust removal system to reduce dust emissions to the environment. The system consists of a telescopic saw blade cover and a connected vacuum with a fan, a separator, a filter and ducts. Thisfilters air efficiently, lowering quartz dust levels in the production hall.

MAINTENANCE

The Saw E9 is a low maintenance machine because there are no hydraulics. The control system gives clear alerts, and the data log and status display make troubleshooting easy. Remote troubleshooting via a Wi-Fi connection is also offered as an option.

BUILT-IN SAFETY

Like all Elematic machinery, safety features are built in. The Saw E9 features derail protection to reduce the risk of the machine falling over. It is equipped with a fast blade stopping mechanism and a system to prevent the blade lowering when not it is not rotating.

The machine meets all EC Machine Directive requirements. It is delivered with comprehensive operator, maintenance and safety manuals in the required language.

CONSTRUCTION

The Saw E9 moves along the side rails of the casting bed. The blade line is indicated with a laser light.

Automatic operation (option) of the machine is enabled with a laser positioning system. The laser sensor is located at the front of the machine and its counterpart mirror is located at the end of the casting bed.

Compatibility

Benefits

-

Automatic positioning and user programmable cut cycles

-

Product-specific cut programs

-

Fast cuts and long blade life

A part of

Precast products

Software

Do you have questions? Contact us!

or