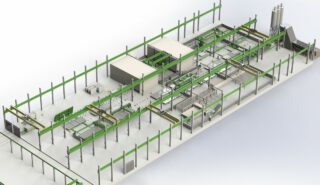

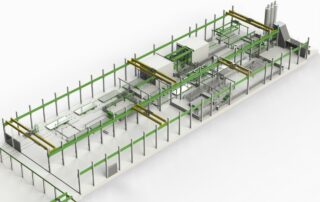

Investing in a new fully automated precast plant

Precasters, who want to establish a new fully automated precast plant and plan high production volumes from the very beginning, reap the rewards from automation’s full potential. Automatic machines, combined with fully automated production lines and all plant operations, bring significant long-term benefits.

Elematic EDGE production lines and machines are specially designed for precasters seeking very high capacity, a wide product range, and highly automated precast production. EDGE is the ideal solution in markets where precast is generally adopted as a building method and demand is high.

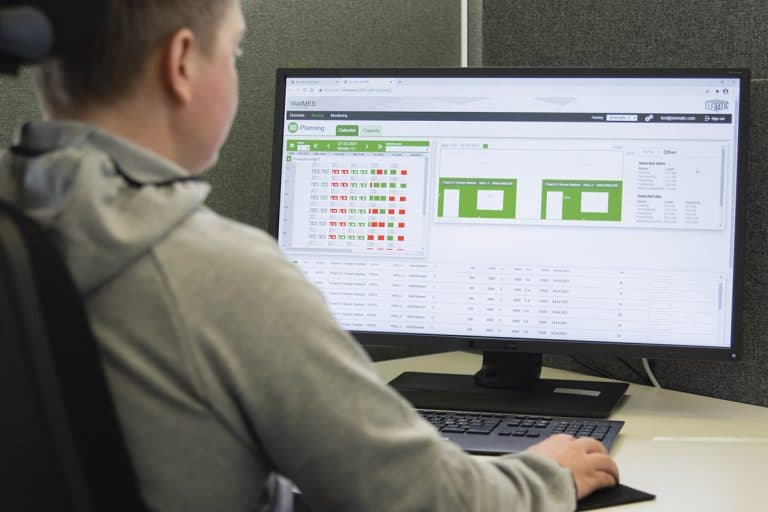

EDGE includes state-of-the-art machinery, the highest possible automation level, and a Plant Control precast production planning system– a cost-efficient solution for optimized production control, real-time production flows, secured uptime, controlled material consumption. BIM software can be connected to Plant Control and extend control from structural design through production and to the construction site.