EDGE Double Wall

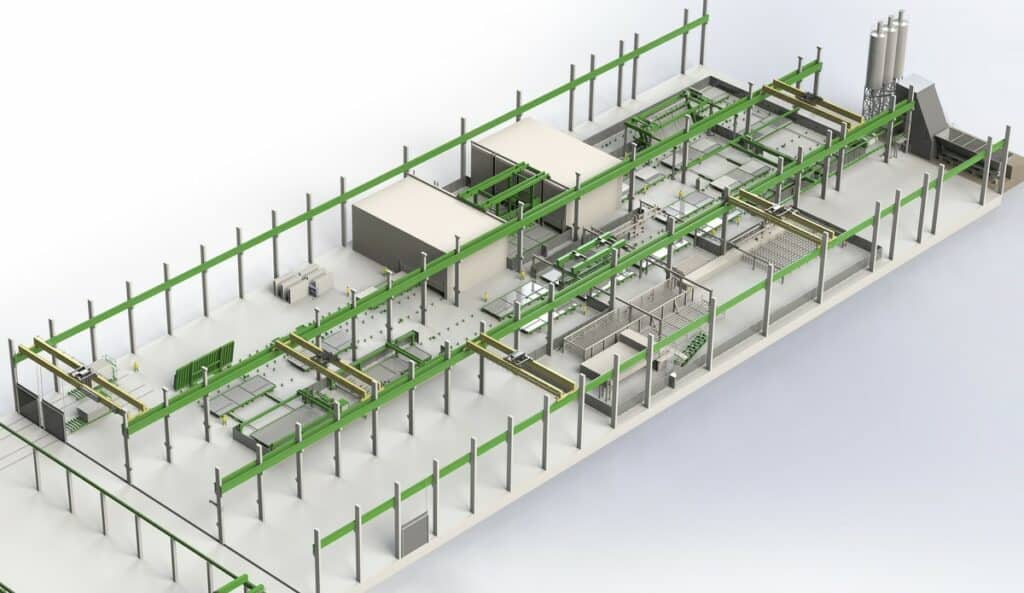

The EDGE Double Wall automated production line is a state-of-the-art system specially designed for high capacity, highly automated double wall and filigran element production. Choose EDGE when a high annual production capacity of even 6 pallets/hour is required.

EDGE Double Wall Line*

| Theoretical production capacity | even 6 pallets/hour |

|---|---|

| Personnel | 25-30 |

| Production area | 10,000 m2 |

| Land area | 50,000 m2 |

| *All figures are estimates |

AN AUTOMATED CIRCULATION LINE

The double wall line needs an area of 10,000 m2 for production and service, with a total land area of 50,000 m2 required for operation.

The EDGE Double Wall is a circulation line – tables move automatically along their production steps for continuous line operation. Fully automated concrete transportation and an automatic shuttering station further enhance the productivity of the line.

The sturdy steel mold tables have a high load-bearing capacity of 600 kg/m2. There can be 75 curing places, and requires 25-30 personnel to operate.

Some special functions, such as turning devices, for example, are needed when manufacturing double walls. You can also use any free capacity to produce filigran floors at the same plant.

PROCESS DESCRIPTION

The double wall process begins with demolding preparations. Before tilting, the magnets of the upper shutters are opened, the shutters are pulled aside, and the magnets are closed. The table mold is then tilted up at a hydraulic tilting station, which allows the lifting beam to be fastened to the lifting loops of the wall panel. The wall panel is lifted to the finishing area if needed, or taken directly to the storage rack, then the table is tilted down.

The de-shuttering robot scans the position of the shutters and moves them to the cleaning conveyor. There, the table is driven through the cleaning and oiling machine. The shuttering robot picks up the shutters from the active cross conveyor or storage rack and places them on the mold table.

Next is manual furnishing. The filling parts and electrical boxes are placed according to plotted markings made by the robot or by the laser projector located above the working station. Window and door opening molds, as well as spacers for steel mesh, are placed. The steel mesh is placed on the table mold, and lattice girders are placed on the table — along with any additional reinforcements or parts.

The concrete is then spread and compacted at the casting station. After curing the double wall shell A, shells A and B are connected and driven to the curing chamber. Empty pallet left from shell A is driven back to circulation.

INNOVATIVE, ACCURATE SHUTTERING ROBOTS

Innovative shuttering and deshuttering robots for EDGE Double Wall are designed to keep pace with a high standard of double wall production.

The automated robot places shutters on the table, either from active or passive storage. Depending on your phase time need, it may feature a deshuttering function — or a separate deshuttering robot can be used.

The shuttering robot comes with an automatic lubrication system for moving and wear parts, ensuring a long service life for this fast, stable and accurate automated shuttering solution.