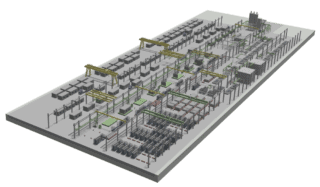

Water recycling device S5

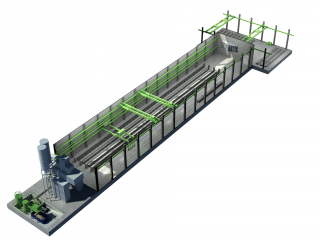

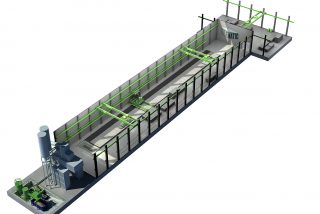

Water recycling device S5-24 is intended for cleaning dirty water from precast factory’s processes. It removes solid material by settling and filtration. It can also remove EPS and fibres. It does not remove chemicals or alter pH, etc.

Water recycling device S5-24

| Dimensions: | |

|---|---|

| Width | 1120 mm |

| Length (operation position) | 2404 mm |

| Height (operation position) | 2275 mm |

| Length (maintenance position) | 2916 mm |

| Height (maintenance position) | 2522 mm |

| Weight (empty) | 718 kg |

| Weight (operation) | 1300 kg |

| Inlet water: | |

| Solids | max. 50 000 ppm (5%) |

| Max stone particle size | D 4 mm |

| pH | 7 – 13 |

| Outlet water: | |

| This performance level can only be achieved by using original Elematic filter, item 132 3010. | |

| Solids (when inlet max 500 ppm) | less than 15 ppm |

| Capacity: | |

| Inlet water solids 500 ppm | 1 m3/h |

| Inlet water solids 10 000 ppm (1 %) | 0.7 m3/h |

| Operating conditions: | |

| Operating temperature | +5°C … +45 °C |

| Electrical: | |

| Electrical Power supply | P+PE, 230 V, 50 Hz |

| Connecting power | 3 kW |

Water recycling device S5-24 is intended to be used together with settling bonds/tanks so that it pumps dirty water from a bond/tank, cleans it and pumps the treated water to clean water bond/tank. The device can be combined into different kind of recycling processes.

OPERATION

Inlet water pump transfers dirty water from e.g. settling bond to the main tank of the Water recycling device S5-24. There the solids gravitate to the bottom where they are slowly transferred up with a scraper conveyor. The conveyor is only partly immersed in water, which means that the wet solid sludge has time to drain water out when it is above water before it is dropped to a hopper (not included).

The device is operated with a control panel with touch screen panel. It can be run in manual and automatic mode. The operation mode, pause and cycle times can be adjusted. The screen displays the state of the device, and operation data e.g. clean water flow, water level as well as cumulative amount of produced clean water.

SERVICE

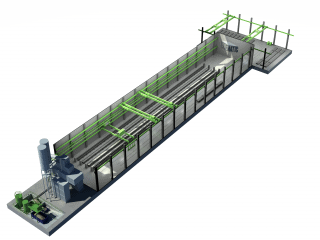

The inner part of the machine can be tilted to service position. The conveyor plates can be replaced in this position and also other service task can be performed.

BUILT-IN SAFETY

The Water recycling device S5-24 meets EC Machine Directive requirements and comes with thorough and clear operator, maintenance and safety manuals in the required language.

STRUCTURE AND FEATURES

The recycling device consist of a steel frame, a container for dirty water, a conveyor for removing solid material from the bottom to a hopper (not included), a submerged pump for pumping dirty water to the machine, pump for pumping clean water out trough a filter, tank and pump for flushing the filter and control system. Touch screen control panel is fixed in the front of the machines. There is also emergency stop button. There is a flow sensor to measure the flow of clean water (clean means treated water).

The main tank is coated with plastic plates, which act as wear plates.

REQUIRED ADDITIONAL ITEMS

Filter package 50 pcs

OPTIONAL ITEMS

Sand separator

ADDITIONAL INFORMATION

A level switch for clean water bond is not included. In the basic set-up the clean water bond will overflow to sewer if overfilled. A level switch can be added as an option to the system, if it is considered necessary by the customer.

Filter must be changed approximately once a week. If the solid content is higher or there is other material, which accumulates in the filter, more frequent replacement may be needed. Changing the filter takes app. 15 min.

The blades of the conveyor are wear parts and must be replaced periodically.

The suitability of the device must be checked prior to order. Water analysis must be available for Elematic for assessment. Also the surrounding process: settling bonds, tanks, etc.

The customer is responsible of the acceptability of the treated water into those uses the customer intends it to be used. Elematic does not guarantee the cleanliness of the water in any other sense than what is mentioned in this document (Reduction of solids, EPS, plastic fibres. Complete removal is not guaranteed, only reduction).

Elematic can provide specification when water is used in precast production with Elematic equipment excluding use as mixing water for concrete.

Communal water department sets limit for water intake to sewer system.

National codes set the requirements for mixing water for concrete production.

Parts and services

Do you want to learn more? Contact us!

or