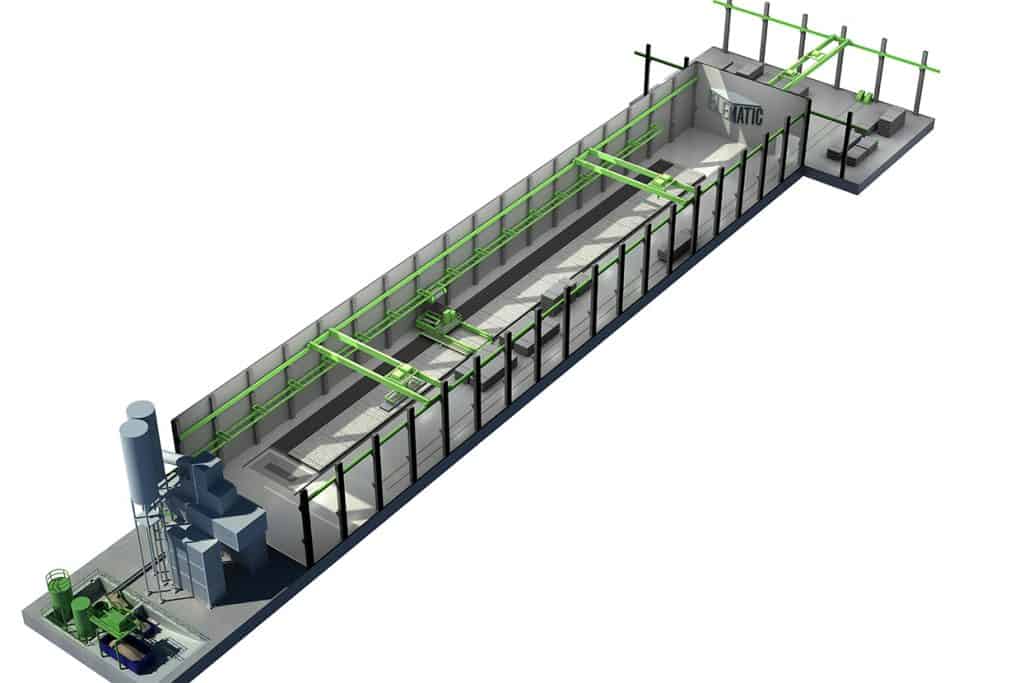

Foundation line

The Elematic foundation line offers a highly productive way to manufacture high quality piles for any building foundations and soil conditions.

The foundation line covers the entire process from concrete batching to storage yard management. The line requires a production area of 3 000 m2 and a storage yard. The Elematic foundation line can be an indoor or outdoor factory.

Foundation line

| Capacity | 1000-2500 m/day (one casting) |

|---|---|

| Personnel | 10 |

| Production area | 3000 m2 |

| Land area | 10 000 m2 |

| No. of parallel molds | 18-33 pcs |

| Typical length of molds | 80-100 m |

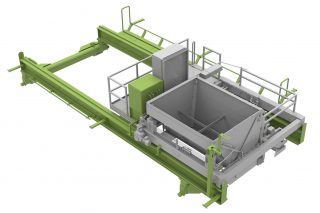

Equipped with a highly efficient pile casting machine, up to eight parallel pile molds can be cast at once on the Elematic foundation line. It features a compact mold layout that makes pile length adjustment, reinforcement, and demolding fast.

Efficient casting and compaction of concrete, performed by the casting machine, make piles strong. Curing can be speeded up by an additional heating system. Heating on the line is based on hot water circulation.

The foundation line is designed and manufactured based on the required dimensions of individual piles and the total production capacity. A typical pile cross section is 350×350 mm, and the length of the individual pile can be adjusted by means of block outs.

Automatic concrete transportation and casting into compact molds ensure up to 3 km of ready-to-install piles per day.

PROCESS DESCRIPTION

Precast pile production takes place in 9 functional steps:

- Batching and mixing

- Concrete transportation

- Mold preparation

- Reinforcement and furnishing

- Casting and compaction

- Curing

- Demolding

- Mold cleaning and oiling

- Storing

The process starts with reinforcement and furnishing. The reinforcement is placed in the casting mold. After that, the pile casting machine is used for casting of molds. The machine moves along the molds and concrete is dosed into the molds. Vibrators are used for compacting the casted concrete. After casting, lifting loops are placed into the piles manually.

The piles are cured on the molds overnight and then removed from the mold either one at time or in bundles by using a custom-designed lifting beam. The ready-made piles are then transported to the stockyard and the molds are cleaned and oiled for next casting.

SAFETY

All machines on the foundation line meet EC Machine Directive requirements. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Compatibility

Benefits

-

Up to 3 km of piles per day

-

Fully adjustable to different lengths

-

Low labor requirement

Machinery on the line

Precast products

Parts and services

Do you have questions? Contact us!

or