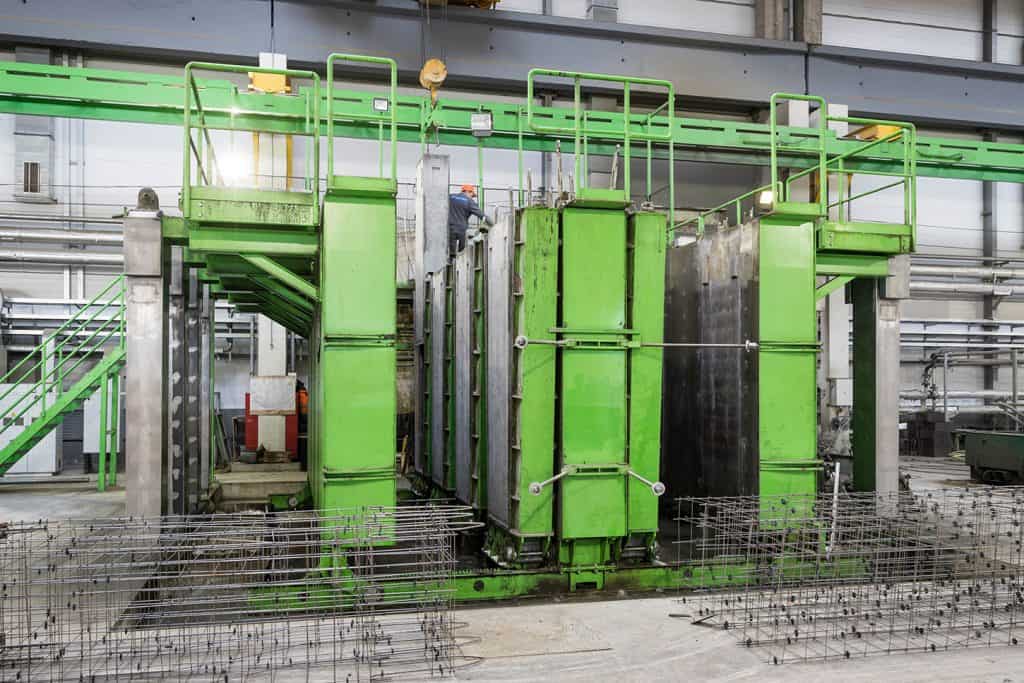

Ventilation shaft mold

Elematic ventilation shaft mold is designed for the production of ventilation shaft blocks for multi-storey construction.

Ventilation shaft mold (5+5)

| Ventilation shaft 350 x 450 х 2990 mm | max. 3 / casting |

|---|---|

| Ventilation shaft 350 x 950 х 2990 mm | max. 2 / casting |

| Length | 6,800 mm |

| Width | 5,800 mm |

| Height | 3,455 mm |

| Weight | 21,600 kg |

Ventilation shaft mold (4+4)

| Ventilation shaft 400 х 800 х 2860 mm | max. 8 / casting |

|---|---|

| Ventilation shaft 400 х 800 х 2660 mm | max. 8 / casting |

| Ventilation shaft 400 х 800 х 2360 mm | max. 8 / casting |

| Length | 6,760 mm |

| Width | 5,900 mm |

| Height | 3,455 mm |

| Weight | 21,600 kg |

Ventilation shaft mold (2+2)

| Ventilation shaft 550 х 1510 х 2780 mm | max. 2 / casting |

|---|---|

| Ventilation shaft 550 х 1300 х 2780 mm | max. 2 / casting |

| Length | 5,400 mm |

| Width | 6,200 mm |

| Height | 3,455 mm |

| Weight | 19,600 kg |

Ventilation shaft mold (4+4)

| Ventilation shaft 400 х 1000 х 2860 mm | max. 8 / casting |

|---|---|

| Length | 7,560 mm |

| Width | 5,900 mm |

| Height | 3,455 mm |

| Weight | 24,600 kg |

Ventilation shaft mold (4+4)

| Ventilation shaft 400 x 800 x 2860 mm | max. 8 / casting |

|---|---|

| Length | 6,760 mm |

| Width | 5,900 mm |

| Height | 3,455 mm |

| Weight | 21,600 kg |

All ventilation shaft molds

| Connecting power | 20 kW |

|---|---|

| Power supply | 3P+PE 400V 50 Hz |

| Remotely controlled |

The ventilation shaft mold is a customizable product, and thus, the dimensions are adapted to the each case. Typical sizes for ventilation shafts are: 350-550mm X 450-1,510mm X 2360-2,990mm (height).

OPERATION

The mold is manually locked for casting and curing with latches located at the end of the walls.

The number of ventilation shafts casted at once depends on their size, and thus, the mold is always designed case-by-case.

COMPOSITION

The ventilation shaft mold has a rigid steel structure, which rigid beams also act as rails for the mold walls. In the middle of the basic mold there is a fixed central wall which acts as a stiffening frame to which plate-shaped molds can be attached. The outer walls of the mold (2 pcs) have a plate structure and are reinforced on the inside. The outer walls are equipped with wheels and can thus be moved by rotating the axel.

The walls of the ventilation shaft mold are equipped with heating pipes for curing and electric vibrators integrated into the walls to compact the concrete. The vibrators are controlled with a remote-control device.

The outer walls of the mold have maintenance platforms.

BUILT-IN SAFETY

The ventilation shaft mold meets EC Machine Directive requirements and comes with thorough and clear operator, maintenance and safety manuals in required language.

Compatibility

Do you have questions? Contact us!

or