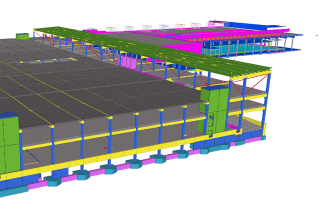

Precast is a method for industrialized construction

Precast is a method of industrialized design, production and construction using precast concrete products. The industrialized process is an advantage that enables quick long-line production, standardized components, the calculated positioning of details, and uncomplicated documentation.

Fast, profitable, and high-quality production and construction

Precast means fast construction time, high profitability, and excellent quality. The industrialized way of producing precast concrete transfers a considerable amount of work from sites to factories.

High-quality precast concrete products are cast on beds or in adjustable molds of different shapes in a controlled environment at a precast concrete plant. Pre-stressing or structural reinforcement is added into the molds or beds before the concrete is cast, compacted, and cured. After complete finishing, the produced concrete elements are transported from the precast plant to the construction site for erection.