Seismically active regions are characterized by high and constantly growing population density. Protection of people’s lives and properties by designing durable buildings is a demanding task.

Precast building systems offer excellent resilience and the capacity for carrying unexpected loads of seismic instability. Compared to conventional building methods, precast is also the most economical solutions for rapid build and rebuild in earthquake sensitive areas.

Precast benefits in seismic regions

Increased need for sustainability, environmentally friendly ways of working, and decreased waste in all project phases, combined with cost pressure and high demand for affordable housing, make the precast technology the economical choice for any low-rise or high-rise building with lots of repetition.

When applied in different frame systems, precast elements have demonstrated high elasticity and structural tolerance during earthquakes. The technology performs as well and even better than cast-in-situ concrete construction. The alternative structural systems and connection solutions are available to achieve desired performance levels.

Design options for building systems are:

- Rigid frame systems (portals; or columns, beams and slabs)

- Shear walls and frames of columns, beams, and slabs

- Continuous wall frame systems

Alternative structural systems are available

Earthquakes induce dynamic loads and realise horizontal and torsion forces that hit the horizontal components of the buildings. The building symmetry and resonant frequency of the structural mass play a crucial role in evaluating the structures’ resilience.

An excellent example of a hybrid precast and cast-in-situ frame structure is the large five-storey R&D center built by Nestle in 2013 in India in zone 4 of seismic activity.

For lateral load resistance from seismic and wind forces, a composite building system was applied. Cast-in-situ shear walls were for lateral resistance, with the gravity load being taken by precast columns, prestressed precast beams, and slabs.

Read more

The design of connections is a key point

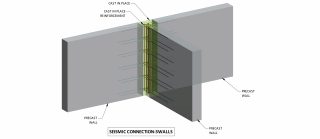

The design of connections is the key point. The induced loads from the earthquake need to be transferred down through the structure into the foundations. Connections between elements are vital to creating the required structural continuity to do this, and they can be interlocking shear walls or corner walls.

Related articles

-

Connections to last

Seismic activity adds its own particular challenges to structural design. This is especially true when connecting…

-

Playing a role in seismic solutions

Knowledge of the seismic performance of precast concrete systems is growing internationally. In India, where a…

Precast knowledge is spreading in seismic areas

Structural design in seismic areas is more complex than standard structural design. Seismic loads and actions are significant compared to non-seismic situations. Seismic design expertise is often local and leans on the principles of cast-in-situ. In many seismically active countries, the designers and building contractors are still unfamiliar with precast concrete technology’s seismic performance.

However, knowledge about the successful use of precast in severe seismic countries like New-Zealand, Japan, Italy and the USA is spreading. Also, the design codes related to seismic design are evolving fast. The 30-storey MGM Grand Hotel, opened in 1993 in Las Vegas, USA, is a good example of a massive precast concrete building in an area with a high building density and a high risk of earthquakes.