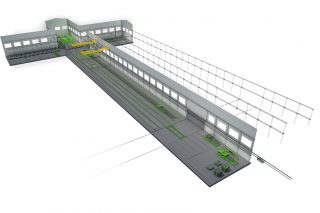

Caster E9

The Caster E9 is a casting machine for automatic and high capacity casting of half-slab and solid slab with wet concrete on a long bed. It also compacts the casted concrete and runs on the rails of the production beds.

Caster E9-40a

| Width | 3095-3995 mm |

|---|---|

| Height | 1780 mm |

| Length | 3770 mm |

| Weight (empty) | 6000-8000 kg |

| Hopper volume (water) | min. 2.8-3.8 m3 |

| Casting capacity (wet concrete, S3) | 40 m3/h |

| Width of the slab, max | 2.6-3.4 m |

| Casting speeds, estimated | |

| 60 mm | 3-4 m/min |

| 80 mm | 2.5-3.5 m/min |

| 100 mm | 2.6-2.8 m/min |

| 150 mm | 1.3-1.85 m/min |

The Caster E9 is automatically operated. It receives a bed production plan from the Plant Control FloorMES system via Wi-Fi or USB and casts the slabs with the correct width and length by opening and closing gate valves. The gate valves are 155 mm wide and they are operated with compressed air. The position of the machine is determined by a laser positioning system.

The concrete is dosed correctly by an electrically driven pocket feeder and the feed is adjusted based on the thickness of the slabs, which is measured with laser sensors.

The concrete is compacted with T-type vibrators after casting. The vibrators are automatically lifted when they go over a side form and lowered down again afterwards. The horizontal position of the vibrators is adjusted manually before casting commences. The vertical down position is adjusted with electric motors.

A device for making the grooves in the slab surface after casting is included.

The electric power is fed via an overhead bucket gantry, which also supplies the concrete automatically. The casting machine pauses the casting if the concrete level in the hopper gets too low. Operation resumes immediately when more concrete is dosed into the hopper.

OPERATION

The Caster E9 has four-wheel drive and two lifting points. A touch screen interface is provided for ease of operation and this also provides information about the machine status, as well as clear alert messages.

An on-board air compressor is provided to supply pressurized air for the actuators.

A power feed from the Distributor E9 is needed for electrical operation.

The casting machine can be moved from bed to bed using an Elematic Side Shifter E9 or a crane.

Automatic casting requires a consistent quality of concrete from the B&M plants. Depending on the stability of the concrete quality, the slab quality may need to be visually monitored during casting.

Hearing protection must be used when working close to the machine.

BUILT-IN SAFETY

Like all Elematic machinery, safety features are built in. The Caster E9 meets EC Machine Directive requirements and comes with thorough and clear operator, maintenance and safety manuals in the required language.

A part of

Precast products

Required

Do you have questions? Contact us!

or