Half slab

Precast half slabs are well-suited for a floor structure in apartment houses, villas, and cottages. They are a valid choice for buildings with a lot of plumbing and holes in the floors. The slab system acts as permanent formwork.

Precast half slab – an ideal choice for flooring with extensive plumbing and holes

Compared to cast-in-situ methods, a half-slab structure saves man-hours and material costs. As the name implies, the half slab is only a half-precast slab, which requires additional reinforcement and concrete topping in-situ. The half slabs need underneath support before topping pouring. Prefabricated half or filigran slabs – as they are sometimes called according to the registered trademark of Filigran Trägersysteme Gmbh & Co. – are usually produced as 60–100 mm thick and 1.2-4 m wide precast products with a 2–6 m span. The final floor thickness, including cast topping, is usually 200-260 mm.

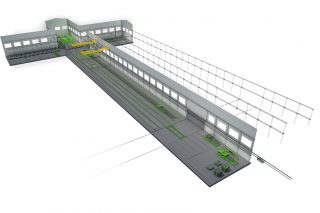

Elematic half slab long line is a fast and advanced technology to produce non-stressed and prestressed half slabs of varying lengths and widths. Half slab can have a plain surface with lifting loops, but usually, it comes with a static reinforcement made by lattice grinders, which provide good bonding with the cast topping.

Prestressed half-slab can be slipformed on a long line or wet cast in molds. A non-prestressed half slab is called filigran or filigree and is wet cast on a long line or in circulation molds. The filigran slab is a reinforced typically around 60-80 mm thick element with lattice grinders on its surface. The slab is usually broad and short, e.g. 3 x 3 m or 3 x 6 m.

Application

The precast half slab is a floor deck element and used in residential and commercial buildings. Industrial and parking facilities as well. It is beneficial in structures with a considerable amount of plumbing and other building service routes and holes installed in the floor structure.

Advantages of the half slab

- Combines precast with in-situ pouring

- In-situ concrete topping forms a monolithic structure

- Fast to install compared to using cast-in-situ molds (but slower compared to hollow core)

- Durable

- Fireproof up to 240 min

Production lines

Do you have questions? Contact us!

or