Building for the data boom: Elematic’s solution for industrialized precast accelerates data center deployment

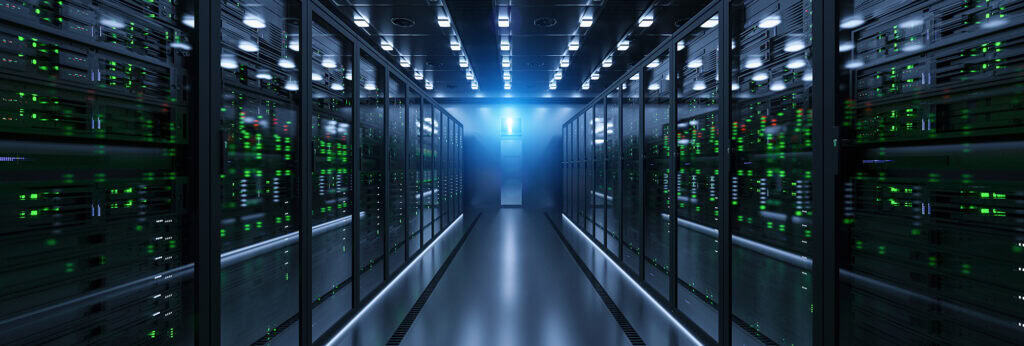

We are currently experiencing a tremendous demand for digital infrastructure. Data centers, which serve as the backbone of the digital age, are rapidly evolving to meet the needs of artificial intelligence, cloud computing, edge services, and sustainability. To ensure that these facilities are scalable, secure, and environmentally responsible, efficient construction, innovative design, and forward-thinking engineering are essential. At Elematic, we believe that data center projects require an industrialized precast construction solution that accommodates the scale and speed of today’s industry while also meeting sustainability standards.

The early 2000s saw the rise of colocation data centers, where customers rent space for their own hardware. However, these facilities are no longer sufficient to meet current demands. The rapid adoption of cloud computing and artificial intelligence has created an urgent need for the global construction of more data centers.

So, what limits data center growth? Many projects are stalled due to slow and labor-intensive construction processes, leading to millions in additional costs and lost revenue.

Here are the key challenges:

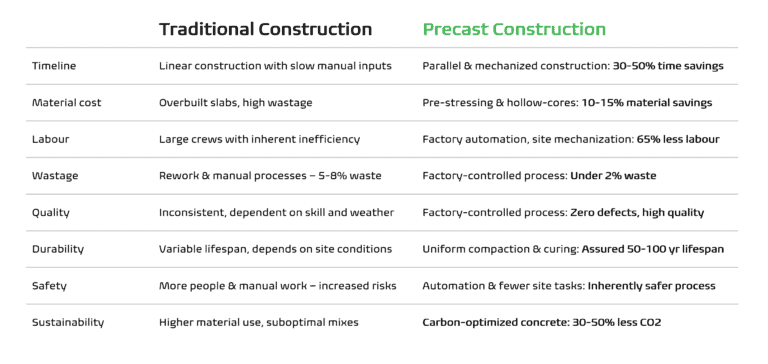

- Speed: Traditional construction cycles take 12 to 24 months, delaying time-to-revenue.

- Scale: Conventional builds encounter capacity and labor constraints quickly.

- Repeatability: Achieving speed and scale is meaningless without quality and precision.

- Emissions: Concrete-intensive construction faces increasing pressure to comply with carbon emission regulations.

As Teppo Voutilainen, CEO of Elematic, puts it: “Speed, scale, and repeatability used to be trade-offs. Precast makes them your strategy.”

Share for others to enjoy this, too!

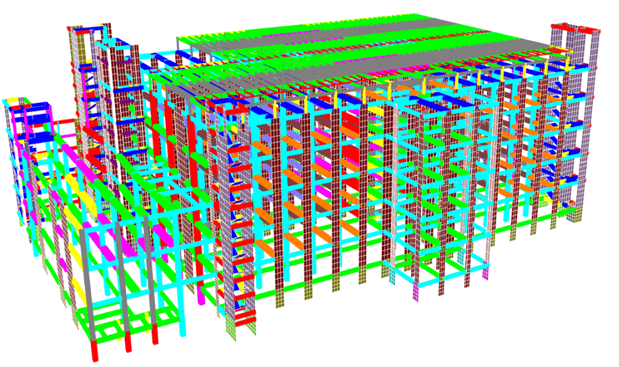

Building data centers with precast concrete

In traditional construction, projects and buildings are often treated as unique, one-off endeavors. In contrast, industrialized construction views the building process as repeatable and scalable. What if data centers were built using precast concrete? By opting for precast instead of cast-in-situ construction, the overall construction time for data centers can be reduced by 30 to 50%, and labor requirements can decrease by up to 65%, resulting in significant cost savings.

Benefits of constructing data centers with precast include:

- Parallel workstreams: Precast elements are produced off-site while site prep happens on location.

- Consistent output: Factory production with minimal on-site curing, weather disruptions or coordination bottlenecks.

- Factory controlled quality: Controlled & highly automated production environment eliminates defects and product variance, minimizes rework & waste, and reduces labor needs.

- Simple on-site installation: Prefabricated elements are quick to install and require fewer workers, significantly speeding up frame erection.

- Structural Efficiency: Optimized design, pretensioned prestressing, and concrete compaction reduce material use while maintaining strength (EN1168).

- Lower carbon footprint: Optimized mix design and reduced material use help cut the embodied carbon of structural elements by 30-50%. Also, through our partnership with Carbonaide, Elematic now enables CO₂ curing in precast production, permanently storing captured carbon in concrete.

- Sustainability that scales: Standardized elements simplify ESG compliance across regions, making it easier to meet procurement and reporting requirements from day one.

Benefits of precast itself should be noted. Precast does not burn, melt, or rot. It becomes more rigid over the years. High-quality precast does not breed any harmful microbes, either. Precast concrete has excellent thermal, moisture, and sound insulation properties as well as high fire resistance. Even better, there’s minimal need for maintenance.

Precast does not interfere with radio signals, local Wi-Fi, or internet networks, making it the most technology-friendly material in the increasingly wired living and working environment.

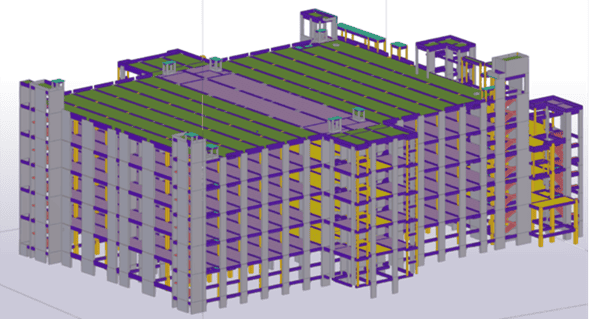

Elematic’s solution for industrialized precast

Choosing to build with precast is only part of the equation. It’s equally important to ponder how and where the elements are manufactured. From the plant to the job site, we at Elematic deliver everything needed to plan, produce, and install precast efficiently.

Elematic offers two types of precast factories: traditional fixed-location plants and modular plants. Both are always designed based on case-specific production needs and enable production of variable element sizes. The latter can be set up on-site or in a regional hub, reducing logistics costs. After project completion, the production equipment can be relocated or repurposed, maximizing long-term investment value.

We do not only deliver and set up precast plants, but we also promise long-term partnership for optimized production. This equals to a range of services; training your crew for effective production, help setting up the right maintenance programs to avoid unexpected downtime, and global precast expertise available to solve any issue in production or maintenance.

Of course, the data centers themselves need to be designed as precast buildings, too. We can help in designing buildings for efficient manufacturing and assembly, saving time and costs. We also keep your schedule on track by guiding your team in best practices for fast and safe installation.

With faster construction, data centers are up and running quicker, unlocking revenue faster. The first data center projects have already been finalized with our technology – if you are a developer looking to speed up your data center projects while avoiding the bottlenecks of conventional construction methods, we are here to help.

Contact us to learn more about precast data centers!

or