Elematic’s SEMI, PRO & EDGE go hand in hand with Eurobend’s machinery

SEMI

Elematic’s SEMI technology level plant is an easy startup of precast production with a low investment. It is perfect for those who see the smaller capacity as an opportunity: precast pioneers, precasters who only need a few products, builders who need production for just one particular project.

Eurobend’s machines that accompany the SEMI version include an entry level (straight bar fed) flexible mesh welding line (with optional modules for increased capacity) together with either a single-line or flexible multi-line (offering automatic diameter changeover) rotor straightening and cutting machine and an entry level rebar bending machine.

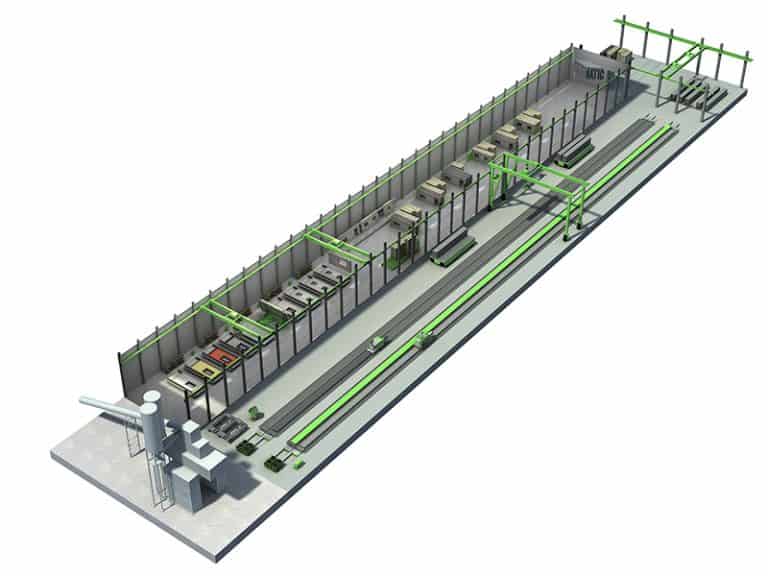

PRO

Elematic’s PRO production lines and machines are especially designed for precasters who need to produce different types and larger volumes of precast products. It is ideal for companies that already have some experience in precast.

For this mid-range solution, Eurobend suggests an increased capacity (straight bar fed) flexible mesh welding line, or a fully automatic (coil fed) machine version for more demanding precast operations, together with a flexible multi-line (offering automatic diameter changeover) rotor straightening and cutting machine, an advanced rebar bender version (either two- or three-dimensional model) and a shear line for processing larger diameters of straight bars.

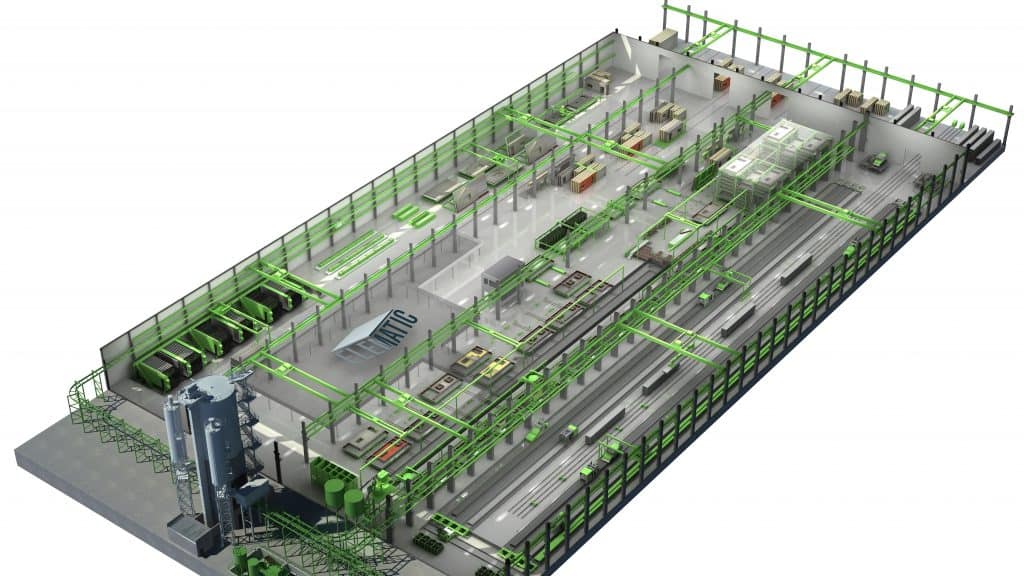

EDGE

Elematic’s EDGE production lines and machines are especially designed for precasters seeking very high capacity, a wide product range, and highly automated precast production.

This high capacity production line will require either a flexible (coil fed) or a high output (coil fed) mesh welding line, together with a flexible multi-line (offering automatic diameter changeover) rotor straightening and cutting machine, an advanced rebar bender version (either two- or three-dimensional model) and a shear line for processing larger diameters of straight bars.