Saw E9: safer and better than ever

Together, the three new saw models cover the needs of different types of hollow core manufacturers well.

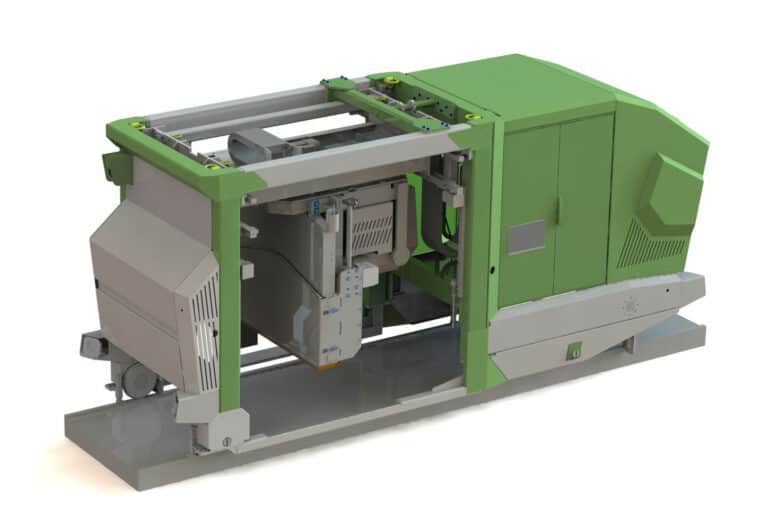

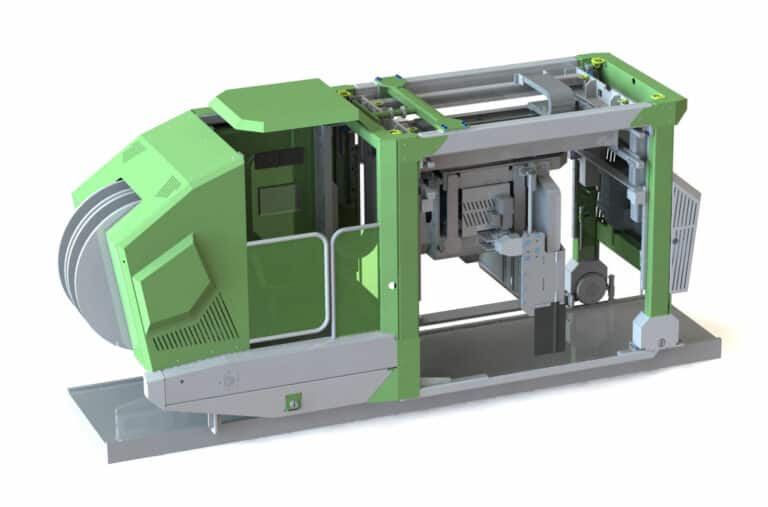

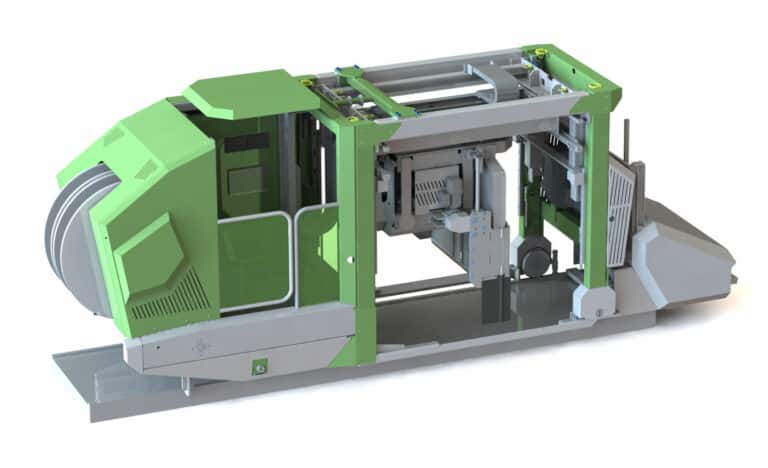

The “Mercedes of Elematic saws”, Saw E9, utilizes cutting-edge technology for a safer, cleaner, and smarter automated hollow core operation.

“Our flagship Saw E9 gets data from the production planning system by using a laser positioning system. So, you just lift the saw to the start of the bed, download the data, and push a button. Then it operates completely automatically until the end of the bed,” notes Eilola.

He also highlights the new safety radars and improved intelligent cutting speed control.

Saw E9-500

- Fully automatic cutting

- Dust reduction (HEPA 13)

- Telescopic blade cover for added safety (blocking shooting diamond cutting pieces and noise)

- Intelligent cutting speed control

- New:

- New blade movement and drive mechanisms for easier maintenance

- Simpler and more reliable mechanisms

- Reduced height to 2560 mm: can fit in lower production halls

- Updated control system with an intuitive user interface and improved cutting control and programs