Elematic’s fleet management services – manage your precast machinery fleet like a pro

Well-functioning precast machinery keeps a plant’s production rolling, so maintaining machinery and ensuring high…

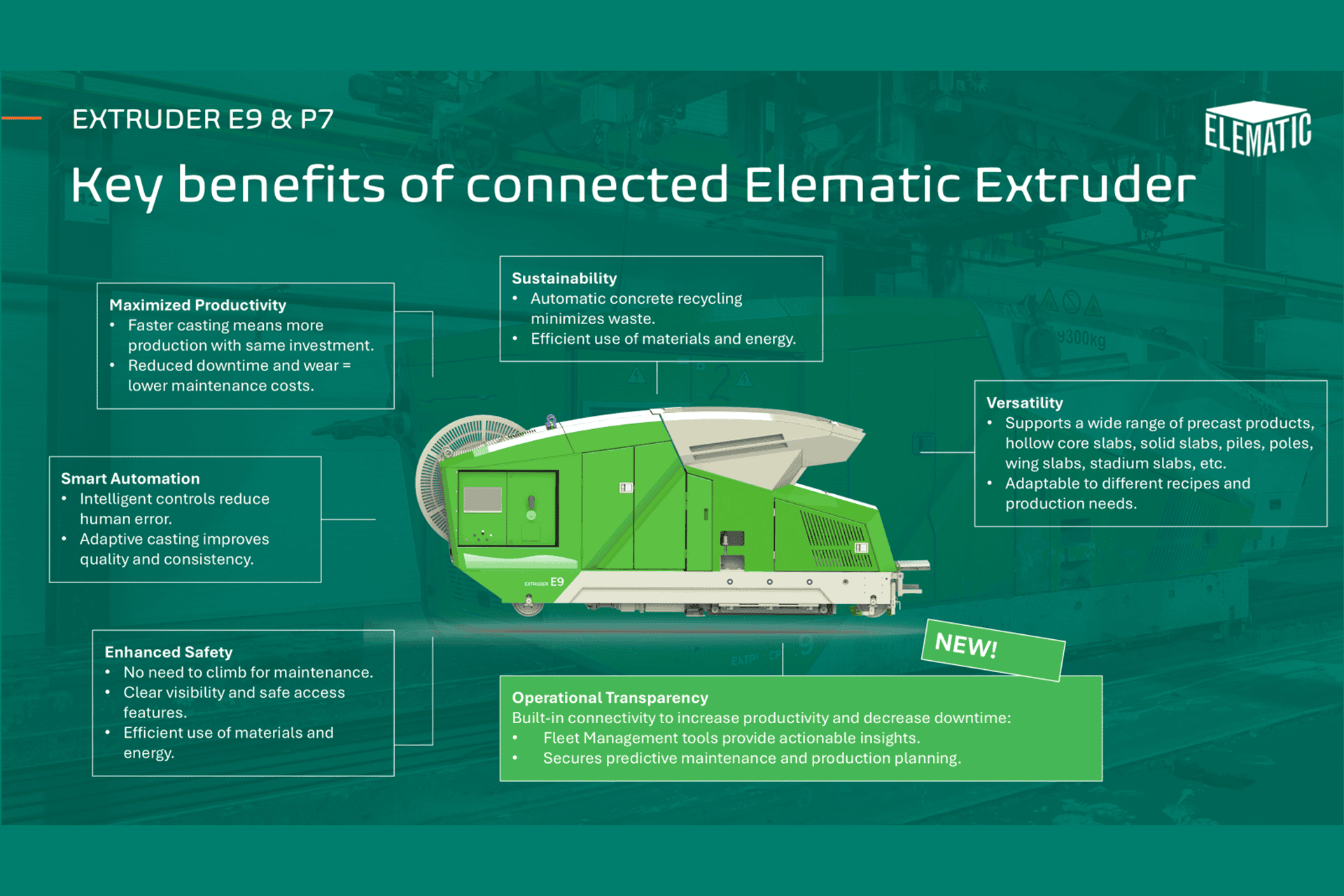

Elematic is proud to unveil its next-generation extruders – Extruder P7 2026 and Extruder E9 2026 – marking a transformative moment in hollow core slab production. These models are the first in the market to feature built-in connectivity as standard, setting a new benchmark for smart, efficient, and transparent precast operations.

What sets this launch apart is not just mechanical innovation, but the integration of built-in connectivity – a feature that redefines how precast production is monitored, managed, and optimized.

Elematic is proud to be the first in the precast industry to offer built-in connectivity as a standard feature in its new Extruder E9 2026 and P7 2026 models. This pioneering move sets Elematic apart, transforming traditional machinery into intelligent, data-driven systems that empower producers with real-time insights and control.

By embedding connectivity directly into the extruders, Elematic eliminates the need for costly retrofits and ensures every customer is future-ready. This innovation supports:

– Real-time visibility into machine performance and production status

– Preventive maintenance that prevents costly unplanned downtime

– Data-driven decision-making for improved casting speed, quality, and resource efficiency

“With built-in connectivity, producers can now see uptime trends daily, weekly, and monthly – and understand what’s really affecting performance. Whether it’s concrete supply issues, parallel line usage, or incorrect operation, the data gives a clear view of the whole process. Alerts and warnings help pinpoint causes and guide corrective actions. It’s a powerful step toward smarter, more efficient production.” – Jani Eilola, Product Director, Elematic

This bold step not only enhances operational transparency but also strengthens Elematic’s partnership with its customers – offering proactive support and continuous improvement through digital services.

For years, precast producers have faced challenges in accessing real-time data from their machinery. Limited visibility into performance and maintenance needs often led to reactive decision-making, increased downtime, and higher operational costs. Elematic’s new extruders directly address this gap.

“Digitalization in the precast industry is still at a relatively low level compared to many other sectors. Today, decisions in concrete element production often rely on individual experience rather than data and facts. We frequently see a conflict between maximizing short-term output and performing proper maintenance, which can lead to a run-to-failure strategy. In the long run, this approach jeopardizes performance and results.” – Lasse Eriksson, VP Service, Elematic

With connectivity now embedded as a standard feature, the Extruder P7 and E9 models can transmit production data to the cloud, enabling seamless integration with Elematic’s Fleet Management digital service. This means operators and managers can monitor machine status, plan production more effectively, and anticipate maintenance needs – before issues arise.

Let others enjoy this, too!

“With built-in connectivity, producers can now see uptime trends daily, weekly, and monthly – and understand what’s really affecting performance. Whether it’s concrete supply issues, parallel line usage, or incorrect operation, the data gives a clear view of the whole process. Alerts and warnings help pinpoint causes and guide corrective actions. It’s a powerful step toward smarter, more efficient production.”

This isn’t just a product upgrade – it’s a shift in philosophy. By turning extruders into smart, connected systems, Elematic empowers its customers with actionable insights. The result is a more resilient production environment, where decisions are informed by data and downtime is minimized.

The connectivity feature also supports preventive maintenance, helping teams stay ahead of potential disruptions. And while the data transmission capability is built into every new extruder, customers can choose to activate it through a subscription to the Fleet Management service, allowing flexibility based on operational needs.

“New digital solutions bring facts to the table, enabling better decisions. For example, when you know the actual remaining lifetime of a feeding screw in an extruder, you can plan maintenance at the optimal time. This allows you to compare the cost of maintenance and parts with the potential cost of lower product quality and extra raw material caused by a worn component. In the end, optimizing production output becomes much easier when you have the facts. That’s exactly what digitalization and connectivity make possible.” – Lasse Eriksson, VP Service, Elematic

“New digital solutions bring facts to the table, enabling better decisions. For example, when you know the actual remaining lifetime of a feeding screw in an extruder, you can plan maintenance at the optimal time.”

Elematic’s latest extruder models, the P7 2026 and E9 2026, are designed to meet the demands of modern precast production with precision, efficiency, and intelligence.

Thanks to their high compaction efficiency, these machines use less cement while still producing top-quality slabs with excellent strength, lightness, and geometry. The E9 model offers high-speed casting, while the P7 provides consistent performance at regular speed. Automatic compaction reduces the need for manual labor and ensures uniform results, even when concrete mix properties vary.

Durability is a key advantage: wear parts are long-lasting, and the machines are designed for dependable operation over time. Safety has also been thoughtfully addressed. Features like quiet operation, protected components, and improved visibility enhance operator protection. For example, the P7 includes a viewing hatch to check mix levels, and the E9 uses sensors to measure concrete volume. Visual and audible alerts further improve safety during operation.

Most notably, the integration of built-in connectivity transforms these machines into smart systems. With real-time data transmission and access to Fleet Management tools, producers gain full transparency over operations, enabling predictive maintenance and informed decision-making.

“We didn’t just upgrade the extruders – we redefined them. By embedding connectivity, we’re giving producers the tools to make smarter decisions, reduce downtime, and optimize every part of their process. It’s about turning data into real value.” – Jani Eilola, Product Director, Elematic

Elematic’s connected extruders are more than just machines – they’re a gateway to smarter, more efficient precast operations. By embedding connectivity at the core of its new models, Elematic is not only ahead of the curve but also helping its customers stay ahead in a competitive market.

“We didn’t just upgrade the extruders – we redefined them. By embedding connectivity, we’re giving producers the tools to make smarter decisions, reduce downtime, and optimize every part of their process. It’s about turning data into real value.”

Well-functioning precast machinery keeps a plant’s production rolling, so maintaining machinery and ensuring high…

Unexpected breakdowns, production delays, workforce shortage, and inefficiencies in the production process degrade…

or