Reducing concrete waste during hollow core production

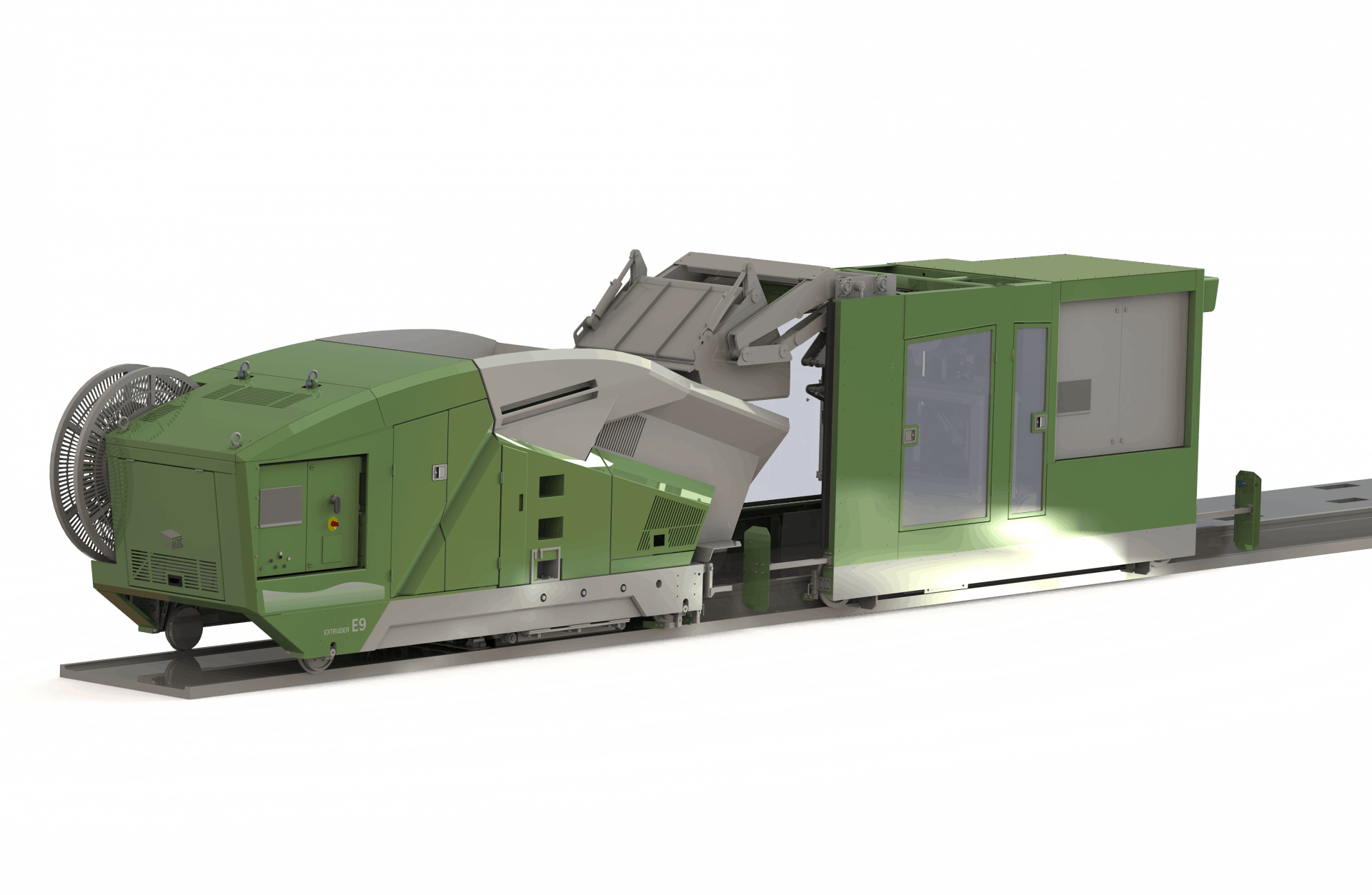

With the new Extruder E9 and Modifier E9, hollow core producers will be able to reduce concrete waste by enabling concrete recycling during production.

Sustainability has always been a priority of the concrete industry. Finding newer, more sustainable ways of working will not only lessen concrete’s environmental impact; finding ways to save on the amount of concrete used also makes sound business sense.

Hollow core is already one of the most sustainable products in construction. During production, it uses up to 45 percent less concrete and 30 percent less steel. Hollow core is mostly used in multi-storey residential, commercial, office and industrial buildings, as well as for vertical or horizontal installations such as walls or noise barriers. Because it allows long spans, using hollow core in construction requires less load-bearing walls, giving more flexibility to modify space during a building’s lifetime.

Waste not, want not

“During traditional hollow core production, concrete that’s dug out to make openings and recesses for HVAC ducts and plumbing goes to waste. Think of how much cement and other raw materials are thrown away because of this. Then add to that transportation and other related costs and you realize how much this practice actually costs a company,” Jani Eilola, Elematic’s Product Director for Floor Technologies, explains.

A new innovation by Elematic could help precast plants plug this big drain on their finances. “The Extruder E9 is the workhorse for casting hollow core slabs. When paired with the Modifier E9, which digs the openings needed into fresh concrete, the Extruder E9 makes it possible to recycle concrete automatically back to the slab production process,” he adds.

How it works

The Modifier features a digging device which moves up-and-down and has two jaws that bite chunks out of the slabs and disposes to the recycling bucket. The bucket is emptied into a receiver silo in the Extruder. Because the Modifier is mechanical, it doesn’t require water or chemicals during the digging process.

The concrete is then fed with a conveyor screw and mixed gradually into the fresh concrete in the Extruder’s hopper. The high speed of the fully automatic recycling process means that the concrete maintains its essential characteristics and quality.

“Unlike with manual concrete recycling, the Elematic solution provides a fast and reliable way to ensure that the quality of the concrete batch remains the same. It’s also much safer than recycling concrete manually and needs less manpower as it is fully automated,” Eilola points out.

Decrease your cost and carbon footprint

Eilola estimates that recycling concrete using the Extruder and Modifier combo can save the average precast factory about €135 000 annually. “Concrete accounts for 50 percent of production costs. So being able to lessen concrete use by 10 percent will already have a big effect on the bottom line. The savings add up once you think of other ways concrete can be recycled – using concrete cut from the ends of slabs, for example or the leftover concrete from making narrow slabs.”

Recycling concrete also contributes to lowering a concrete plant’s carbon footprint. In the EU-area alone, a decrease of CO2 emissions from concrete plants of 540 000 tonnes per year is possible to achieve.

“The Extruder and Modifier can really make a difference in helping precast producers optimize their plant’s production without sacrificing safety, quality or environmental responsibility,” Eilola points out.

“Using the combo can save the average precast factory about EUR 135 000 annually.”

Jani Eilola

Fully automated concrete recycling with Extruder E9 and Modifier E9

New design

- No need to lift the bucket high

- Receiver silo in the new Extruder E9 2019

- Distributor can be kept in automatic mode

Maintain slab quality

- Time limit can be set for recycling i.e. < 20 min.

- Recycled concrete inserted gradually into extruder’s hopper where the recycled concrete is mixed with fresh concrete.

Reduced amount of residual concrete

- A new digging mechanism with a linear movement of the jaw reduces the amount of concrete left on the bed in the process

Do you have questions? Please contact us.

or