How Elematic’s solution for industrial precast saves time and money in car park construction?

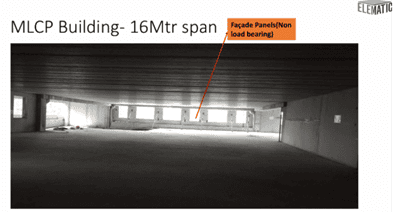

In the construction industry, time is money. Compared to in-situ concrete structures, precast car parks can not only be built in half the time but also enable fitting up to 20% more cars per square meter. This is made possible by the long-span hollow core slabs that enable sturdy car parks to be constructed with significantly less vertical supports.

Common issues with traditional multi-story car parks:

- Build times: Weather delays and concrete curing times drastically slow down project timelines.

- Space inefficiency: Short span lengths result in poor space utilization and hard-to-navigate spaces.

- Resource inefficiency: In-situ concrete requires 60% more labor in comparison to precast technology and wastes material on overbuilt structures.

These issues – and several more – are solved by precast construction. Precast means fast construction time, high profitability, and excellent quality. The industrialized way of producing precast concrete transfers a considerable amount of work from sites to factories.

Precast construction system enables:

- Standardized components: Every precast element is manufactured based on approved drawings and technical specifications, making high quality production on scale easier and quicker.

- Better structural system: Precast, a versatile structural system, offers superior strength, durability, construction efficiency, design freedom taking into account seismic zones, and more resilience to environmental factors.

- Factory precision: A carefully designed production process and the controlled environment enable real-time monitoring of quality and easy adjustments in raw materials, casting and finishing.

- Rapid assembly: Connectors and accessories are built into the precast elements, ensuring a reliable connection of the elements as well as their quick and safe assembly at the construction site.

- High strength: Precast’s excellent load-bearing capacities and possibilities for long spans give more freedom to architectural and structural design than traditional methods.

Building car parks as precast structures makes sense, because not only is money saved and buildings constructed quicker, up to 20% more cars fit per square meter. In other words, it’s possible to build a 20% smaller building and keep the same number of parking spaces.

Benefits of precast car parks:

- Simple & rapid erection: Lightweight hollow core slabs and other precast components are easy and fast to store, handle, and install.

- No shuttering or propping: Prefabricated elements are designed to self-support during erection, eliminating the need for propping.

- Fewer structural components: Prestressed slabs allow for longer spans, reducing the number of vertical supports.

- Reduced foundation requirements: Fewer vertical supports and lower dead weight simplify foundation design and minimize excavation.

Elematic’s solution for industrialized precast

Opting for the precast structural system is one thing; the other is to decide how and where the precast components are manufactured. Elematic’s precast plant concepts offer different levels of production capacity, automation features, and choices of end-product range. The number of required operators varies based on the automation level of the production line. All Elematic production lines can be customized to the specific needs of the individual plant.

We want precasters to be proud of the products supplied to customers. This is why Elematic production lines have advanced, patented, and high-quality technologies that guarantee the best possible end result.

Based on decades of experience with the needs of precast plants around the world, we have created a range of services to support in precast operations and to provide concrete results: improved profitability, better efficiency and higher uptime.

Let others enjoy this, too!

Want to learn more about the benefits of precast car park construction? Leave your questions below, and we’ll gladly tell you more.

or