Already well-known for hollow core floor and sandwich wall production, we now expanded our wall production offering to include state-of-the-art double wall and filigran production lines. Add to that a robot control system, and the result is optimized automation as well as optimal layout and processes for your factory’s specific needs. Double Wall Edge offers the same fundamental characteristics known from our other reliable and efficient wall lines. lines.

“The double wall plant includes much of the technology that is also found in our sandwich and solid wall circulation lines, based on decades of experience. Some special functions, such as turning devices, for example, are needed when manufacturing double walls. You also have the possibility to make good use of free capacity to produce filigran floors at the same plant”, says Elematic’s Product Director Toni Koitmaa.

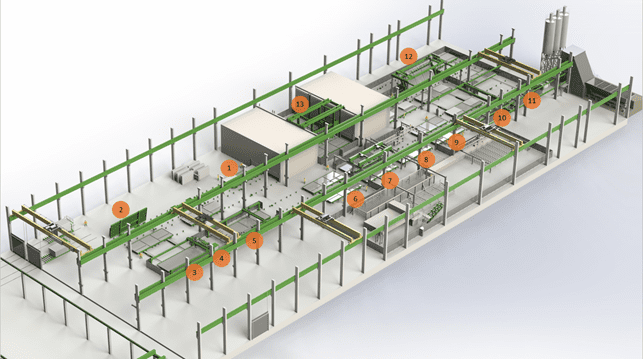

Simulation tool demonstrates the functionality of the layout

As an Elematic customer, you are never alone. Our experienced team of highly skilled precast technology professionals is committed to supporting you with proven technology, high-quality and efficient spare and ware parts service, technical support, and a help desk throughout the lifetime of your equipment.

“With our specialty, the simulation tool, we can demonstrate how the planned layout will work. What happens if you add tables to a circulation line – or take some away? What happens if you have more – or fewer – workers on the shop floor? How does production run if there are different types of elements with significant variations between work phases? The simulation tool helps finding the answers to such questions and thus build the perfect layout for you,” Koitmaa states.

Stable and nimble shuttering robot with a finishing touch

Furthemore, we have developed a new generation of shuttering and deshuttering robots. In the automated process, the robot places shutters on the table from active or passive storage and may, depending on the phase time need, feature a deshuttering function. Alternatively, a separate deshuttering robot may be used.

”In addition to being accurate, it is also fast and stable,” Koitmaa points out, adding that it enriches the market with an innovative, all-new feature that increases its reliability and lifetime.

“ The shuttering robot has an automatic lubrication system for lubrication of moving and wearing parts, which guarantees a long service life for the device,” Koitmaa points out.

Elematic can also deliver robot shuttering for sandwich and solid walls.