Automatic Modifier in your production – 3 things to consider in the process

Are you planning to automate part of your precast production, but not sure where to start? Jarkko Salmensivu shares three basic tips what to think through if you are planning to take an automatic Modifier into use in your production.

1. Factory processes

The modifier can dig, plot and drill water holes on slabs. When you are planning to take the automatic machine into use, go through the types of products you produce and what kind of tasks and processes are currently done manually. Sometimes the elements can be full of details so it may take a lot of time for the machine to accomplish these. In these cases, it may be a better solution to, for example, drill the water holes manually and use the machine in full automation for the standard elements. Automating and standardizing frequent and repetitive processes is where you get the best benefit. Once you know what you need from automation, you need to think about how it will change the workflow in your plant. At first, it will require thorough planning as any other new way of working.

2. IT systems

Machines are controlled with IT systems, so the information management process and data flow are crucial for fluent automation. It starts with product design. Whether you use your own plans, or the plans come from an external design agency, the designs should be smoothly transferred to the factory automation system. You need to ensure that the agency uses design tools from which the data can be extracted and thus used in automatic production, e.g., Tekla Structures.

3. Production planning

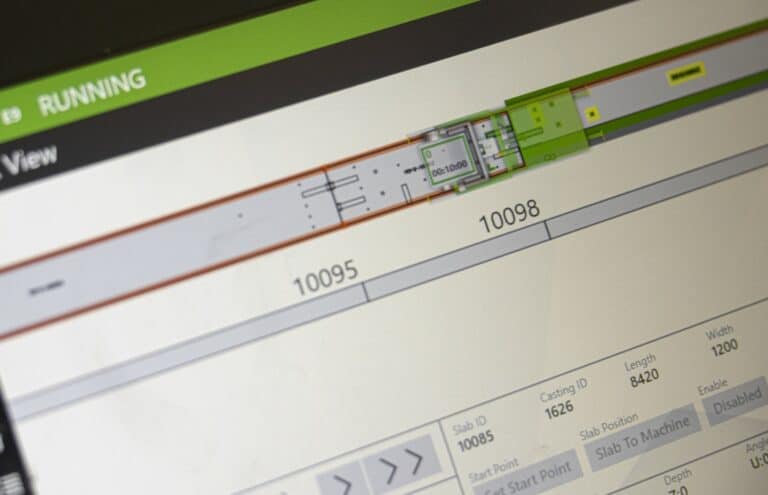

The MES (manufacturing execution system) controls automation and production. The system makes the planning of how the slabs are placed on the bed. Just as essential information as the length of the slab and the location of the openings is where the slab is located on the bed. Based on the bed plan the Modifier knows how to dig the right slab and the right holes. It sounds simple, and it is, once it’s in shape, but in the beginning, you must be thorough. The bed plan needs to have information about the slab properties and locations on the bed, it has to be just right.

The machine can meet your requirements or not, it depends on how well it is controlled. The machine does not automatically do the right thing, it cannot know what is right for your factory. That is why you should be thorough in planning and use time for preparing the backend IT system. patient in the beginning and thorough in planning. When you have successfully commissioned the Modifier to do the right thing, it will do the right thing for the next 10 years.

If you plan to grow and your target is to increase production efficiency, automation is your solution.

Jarkko Salmensivu

LEARN MORE

Want to learn more about Modifier E9? Please, contact us!

or