Efficient design: overcoming construction challenges with precast technology

A well-thought-out design that aligns with construction technology and anticipates on-site challenges is the foundation of successful precast implementation, says Prakash Shah, Vice President of Design at Elematic. Shah leads a team of structural engineers, BIM modelers, and designers in India, delivering global structural design and BIM services using advanced software for quick, efficient solutions.

Design and BIM: building success from the start

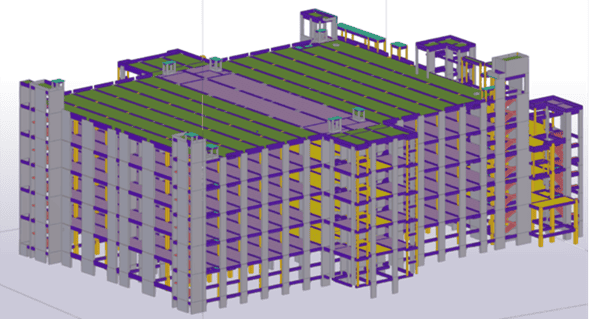

Elematic’s design process leverages Building Information Modelling (BIM) to virtually construct projects before execution. This approach ensures accurate quantity calculations, clash-free designs for smooth buildability, and reliable planning for time and cost optimization.

BIM breaks silos between disciplines by creating a centralized 3D model where architectural, structural, and MEP systems interact seamlessly.

Prakash explains, “By using BIM, we can construct the project virtually before actual work begins. This proactive approach minimizes costly surprises and delays, ensuring a smoother execution process.”

The role of a competent technology partner

Prakash emphasizes the importance of choosing the right partner when adopting precast technology.

“Choosing the right technology partner with extensive global experience provides organizations entering the precast field with a significant advantage. Such a partner shares insights from past implementations, helping avoid costly mistakes and wasted time. Exploring alternatives like site-based production systems, scalable tailored plants, or high-capacity automated plants ensures solutions that meet both immediate and future needs.”

Design drives efficiency

According to Prakash, most challenges in implementing precast technology stem from the initial design stage. Early involvement of an experienced technology consultant ensures architectural and structural designs are precast-friendly, saving time and resources.

He elaborates, “While we can convert any conventionally designed structure into a precast system, achieving true efficiency—speed, quality, and cost savings—requires considering construction technology from the project’s inception. An experienced consultant brings knowledge of production and execution, ensuring optimized designs. It’s not always the design with the lowest material consumption that is most efficient; overly complex designs often lead to higher costs, material wastage, and execution challenges.”

Elematic’s design team in India provides building structural engineering as well as BIM services. The team’s services are not limited to the Indian market, as Prakash and Design team are well-versed in international practices and design standards.

Case studies: real-world impact

- Residential development: A client required 40 mid-rise towers using conventional design. Elematic’s team proposed minor architectural adjustments and a precast framing system with long-span prestressed hollow core slabs and structural walls. The challenge was balancing architectural aesthetics with structural efficiency. By implementing these changes, the project achieved cost savings, and the return on investment for the precast plant was realized within three years.

- Data centers: For a client developing data centers tailored to specific end-user requirements, Elematic provided concept design services. The challenge involved integrating complex MEP systems with structural elements. The team collaborated with all discipline consultants, identified inefficiencies in conventional designs, and proposed a precast structural system with detailed connection designs. This approach ensured feasibility, reduced execution risks, and enabled informed decision-making for adopting precast technology.

- China project: A builder’s in-house team designed a precast system without prior experience, resulting in high costs and complexity. Elematic re-engineered the structure, introducing efficient design principles and modern connection details. The outcome was a 30% reduction in material consumption and a 50% decrease in execution time.

Precast: the future of construction

Meeting today’s growth requirements, complex building designs, and extremely tight project timelines is increasingly challenging – especially with the shortage of skilled labor and unpredictable weather conditions. Under these circumstances, relying on conventional construction methods is no longer practical. When sustainability and compliance with CO₂ norms are added to the equation, precast construction becomes the clear choice.

Precast technology delivers significantly higher productivity compared to traditional methods. It enables optimized material usage through efficient design and accelerates construction speed – often achieving timelines nearly twice as fast as conventional approaches. Mechanized production in controlled factory environments minimizes material waste, supports water recycling, and allows for the reuse of by-products. Additionally, the integration of CO₂ into concrete enhances early strength and reinforces precast as a superior green solution.

Over the past decade, the adoption of precast technology has grown steadily – not only in India but globally. This trend will continue as construction companies recognize that precast solutions not only meet project targets but also deliver long-term advantages. In the near future, precast construction is poised to become the preferred method for development projects.

Prakash emphasizes, “In-situ construction, still common in many regions, cannot meet the soaring demands of today’s construction industry. It is also far from being the most sustainable alternative.” Precast concrete offers an environmentally responsible solution by minimizing waste and emissions through off-site manufacturing in controlled environments. It incorporates recycled materials, provides long-term durability, and enables resource-efficient designs that reduce on-site impacts. Its thermal mass improves building energy efficiency, and the material is fully recyclable at the end of its service life – supporting a truly sustainable construction approach.

The advantages of BIM in precast construction

One of the most significant benefits of using Building Information Modelling (BIM) is its ability to eliminate silos between disciplines. Traditionally, consultants work in isolation, developing designs for their respective areas without full visibility into other disciplines. This fragmented approach often results in inconsistencies, quality gaps, and design clashes that are both inefficient and costly to resolve.

BIM transforms this process by creating a centralized, three-dimensional model that fosters collaboration and clarity. Designers can easily visualize how architectural details integrate with structural systems and how these, in turn, align with mechanical, electrical, and plumbing services. This reduces reliance on assumptions and ensures a cohesive, clash-free design.

Essentially, BIM allows teams to construct the project virtually before actual site work begins, enabling proactive identification and resolution of incompatibilities. In contrast, traditional 2D drawings often leave these issues to interpretation, leading to expensive delays during execution. By implementing BIM and having all disciplines work on a shared model, projects achieve higher accuracy, efficiency, and predictability.

Modern precast production systems further enhance this synergy through advanced programming and automation. Data exchange between BIM and precast plants is seamless – for example, Elematic Plant Control integrates directly with Tekla BIM, synchronizing production requirements without manual input. This reduces human error, improves scheduling, and optimizes production planning, ensuring smooth and efficient delivery across multiple concurrent projects.

Let others enjoy this, too!

Prakash Shah, Vice President of Design at Elematic

Elematic Design Services

Want to know more? Contact us!

or