4 strategic reasons to invest in training for your precast plant personnel

In today’s competitive construction landscape, the efficiency and quality of precast concrete production are more…

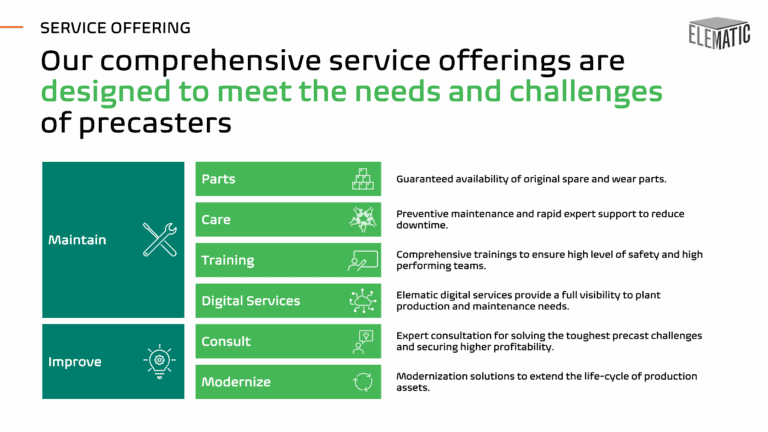

Unexpected breakdowns, production delays, workforce shortage, and inefficiencies in the production process degrade productivity, while aging equipment leads to higher maintenance costs and reduced output and quality. Elematic offers services for its precast customers around the world to maintain their equipment, ensure uptime, and to constantly improve productivity.

The global precast construction market is constantly growing due to precast’s unparalleled durability, structural strength, fire resistance, thermal mass, and usability in all climates. Precast elements are produced in precast plants; however, running one effectively is no simple task. Highly controlled production process with advanced technology, precision and skilled workforce is needed to produce every single wall panel, floor slab, staircase etc.

Through discussions with precasters we have noticed a recurring pattern in the challenges faced by precasters. These typical challenges are mentioned:

All the challenges above cause significant revue losses. For example, you loose 16,200 € in revenue every day if one extruder is not operational while still incurring operational costs. Also, incurred extra cost of one millimeter extra concrete layer due to suboptimal machine settings can add up to 41,400 €/year.

Let others enjoy this, too!

At every precast plant more than one person should know how to safely operate the machines, how to use their operating systems and how to maintain them. For example, how to charge batteries, check sensors to avoid tripping, clean photocell sensors and mirrors, wash the equipment, and maintain extruder nozzle and saw vacuum units, and modifier and plotter inkjet systems.

When there are changes in staff there are changes in know-how. A lot of information leaves the plant, and training is needed for the new mechanics or people responsible for maintenance.

To solve the challenge, we offer three types of training services: digital training library, e-learning program and in-depth training programs for you to make sure that the right competence is always available at your precast plant.

Elematic training packages focus on the best practices and safe procedures to operate and maintain the machines. They are always tailored to the needs of specific precast plants and their production. Remember that operator training is always an investment in your precast plant and its efficiency.

There are two options for tackling precast production challenges: contacting us when unforeseeable factory downtime occurs and the service agreement. Through the first production challenges are solved as they arise. On the contrary, service agreement is a cost-efficient partnership that results in the highest uptime and productivity, achieved through proactive support and quick responses. Here the focus is on preventive maintenance and production improvement before any challenges arise – and if challenges still occur, we try to solve them as soon as possible.

The service agreement, designed to meet the needs and challenges of precasters, is the most efficient way to utilize Elematic’s global expertise for:

This is what our service agreement customers say:

“Elematic experts are always there when we need them and do their best to help us. We always look forward to the time some of the service engineers come on a visit. They have a lot of knowledge, and they are very forthcoming.

Until now, all the people I have been in contact with have always been in a good mood. They are eager to help in any way they can. So, keep up the good work, and I hope we can work together for many years!”

“Elematic prioritizes us, which makes a difference in keeping our production running smoothly. And we appreciate the consistency of your follow-ups and quick responses when needed.

Elematic always finds someone who can give you a proper answer. For us, it is important that the service engineer has hands-on experience with what they do and also a strong knowledge of how the machines work.”

Our digital services offer visibility, uptime, productivity – and everything you need for comprehensive maintenance management and planning. Through the system you can access your machine and production data anytime and anywhere, plan maintenance, manage costs, and secure a high level of uptime.

Depending on your needs, we can manage single machines or connect all your equipment, regardless of the provider, to our maintenance management software, which includes fleet and maintenance management.

With Elematic service agreement, you gain a trusted partner committed to improving your operations and delivering expert support throughout the entire life cycle of your precast plant. No matter the challenge, we are with you every step of the way. Let’s start our journey together!

In today’s competitive construction landscape, the efficiency and quality of precast concrete production are more…

Have you pondered what the benefits of a service agreement could be? Why to have an agreement, when you can easily…

or