Connections to last

Seismic activity adds its own particular challenges to structural design. This is especially true when connecting…

As the construction industry increasingly embraces precast concrete for its efficiency, quality, and speed, seismic design emerges as a critical consideration — especially in regions prone to earthquakes. Let’s explore how precast buildings are designed to withstand seismic forces while ensuring safety, load path continuity, and structural integrity.

Precast concrete systems are increasingly favored in seismically active regions due to their:

Precast performs as well as – from ductility and robustness aspects – cast-in-situ concrete in seismic conditions. Its resilience has been demonstrated in countries like Japan, New Zealand, Italy, the USA, and India where seismic risks are high and building codes are stringent.

Precast structures can be designed using two primary approaches:

Each approach has trade-offs in terms of stiffness, ductility, construction complexity, and labor requirements.

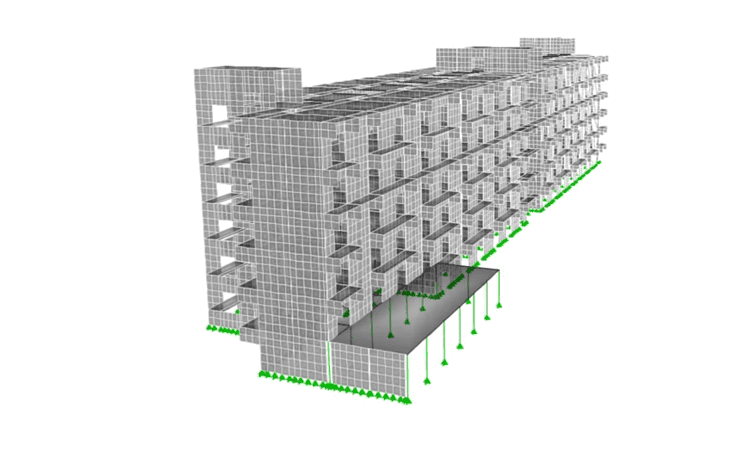

Several structural systems are adapted for seismic performance in precast construction:

These systems must be carefully selected based on building function, height, and seismic zone classification.

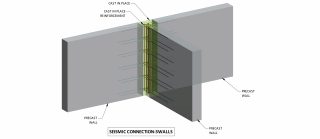

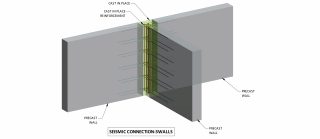

Establishing robust connections is the backbone to the seismic resilience of precast structural frame buildings. They are categorized as:

Proper detailing, such as reinforcement arrangement, loop bars, dowels, and mechanical couplers, grouting and junction concreting provision, is essential to ensure seismic resilience.

Let others enjoy this, too!

Seismic activity adds its own particular challenges to structural design. This is especially true when connecting…

A Concrete Issues reader requested to learn more about wall connections in precast buildings. We asked Assistant…

Beyond seismic design of building for its service life condition, structural performance shall ensure:

These checks ensure structural soundness and safety throughout the building lifecycle.

Precast buildings are not designed to remain undamaged during earthquakes – they are designed to prevent collapse. The key is ductility: the ability of a structure to deform without failing. During an earthquake, cracks may appear, but the building remains standing, protecting lives.

This principle applies across all structural types – precast, cast-in-situ, or steel. What matters is the identification and suitable design of lateral load-resisting system with proper detailing of connections/ joints that ensure lateral load transfer from different area of all floors to the vertical load resisting system and eventually to foundation as continuous load path.

Precast concrete is not just viable in seismic zones – it is often the resilient and economical choice. With proper design philosophies, robust connection detailing, and a focus on ductility, precast buildings can absorb seismic forces, prevent collapse, and protect lives. As global awareness and expertise grow, precast is poised to become a cornerstone of earthquake-resistant construction.

Learn more by downloading Precast Design Handbook. It’s free.

Knowledge of the seismic performance of precast concrete systems is growing internationally. In India, where a…

If the joints are detailed correctly, precast concrete buildings are robust enough to stand tall through an…

or