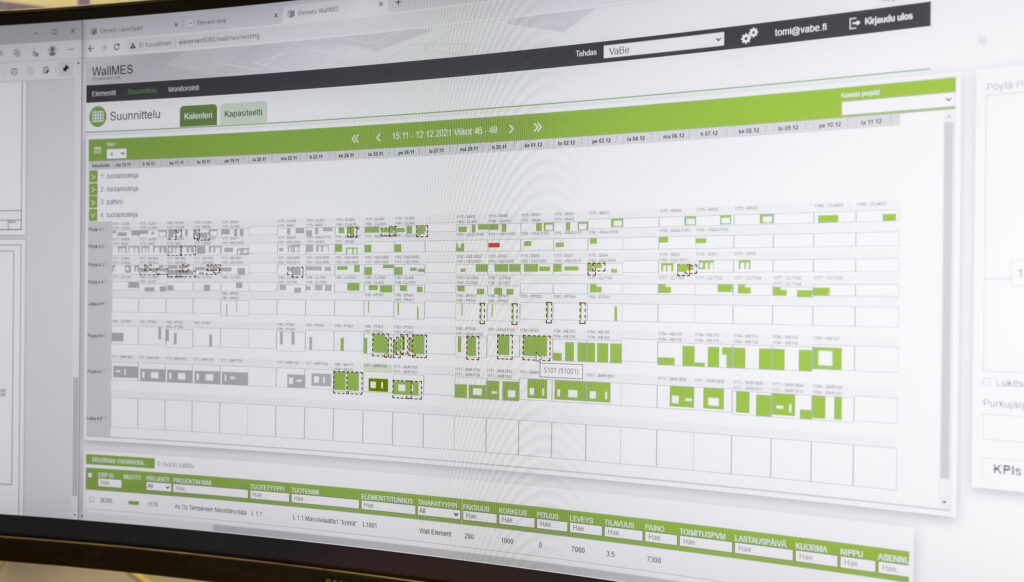

VaBe Oy uses Plant Control’s modules for the production planning of wall elements, also known as WalMES. Currently, the modules for production planning and planning the shipments are being used, but the system is being extended to workflow monitoring and quality control.

The extensibility that the modular system structure offers was one of the main reasons for choosing Elematic Plant Control.

First production planning

The first Plant Control module applied at VaBe Oy was the production planning module. It can also be used to monitor material demand, consumption,

and stock.

”We have close to 1,000 items in stock. Now that delivery times are quite long, it is good to have real-time information about the stock situation,” says CEO Markus Lehtinen.

Project manager Tomi Mäkimarttunen and production designer Sampsa Laakso use the tool smoothly.

“Now, once an element has been fed into the system, it can no longer be lost. Everyone has always access to the latest revision in a clear format,” says Mäkimarttunen.

Laakso highlights the system’s visuality and user-friendly interface. “When I noticed that the system works and can be trusted, it took only a couple of weeks for me to switch to using the new system in production planning,” he explains.

Important project manager

At VaBe, the project manager has played a central role in driving the change forward and actively communicating with Elematic. The old and new systems were kept side by side during a short transition period, and the staff was trained.

Next up are more modules. “We would like to take digital work hour monitoring and quality control into use. They would allow us to monitor real-time workflow and time as well as quality. We have high expectations for improving overall efficiency, once we have full use of the modules and monitoring data,” Lehtinen sums.