How to produce a brick wall appearance on precast concrete?

Looks like brick façade, stands like precast concrete? Yes, that is possible with special manufacturing process, combining precast and traditional masonry.

Our Product Director in wall technologies, Toni Koitmaa, reviews the process step-by-step.

1. Furnish the mold table with plywood

Cover the standard mold tabletop surface with plywood. This is to make the plastic raster fixing easy.

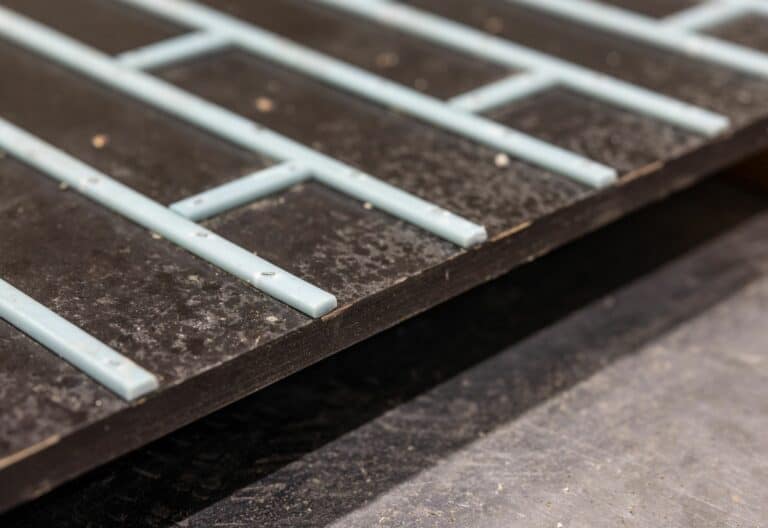

2. Fix the plastic raster on the table

Fix the plastic strips on the plywood with staples. You can measure the places for the strips manually or according to the laser projection.

3. Lay the cloth and the bricks on the table

Place the protection cloth on the table to protect the table against the concrete. The cloth also prevents the concrete from leaking onto the brick surface. Then place the bricks manually on top of the cloth, according to the plastic raster.

4. Protect the brick seam (optional)

This instruction applies if you want the wall to look like real masonry, which means it will be seamed later at the construction state. You can protect the bricks by spreading the fine sand between the seams, to prevent the concrete from reaching the bottom.

5. Water the bricks

It is important to water the brick to prevent them absorbing water from the concrete.

6. Add reinforcement

Place the reinforcement on the mold. The reinforcement is done in the same way as for the traditional wall element.

7. Concrete and finish

Finally pour the concrete into the mold and finish the surface of the element. Compacting the concrete with vibrators on the mold table is not recommended, because the bricks could move, and the concrete would leak more easily onto the brick surface. It is recommended to use self-compacting concrete or poke vibrator with regular concrete.

Toni Koitmaa, Product Director in wall technologies.

Pay attention to these

A brick facade is typically used in the area where new buildings are constructed near to old brick buildings. The new buildings may even be attached to the old ones. To create a coherent appearance, it is important to make the choice of the bricks carefully and make sure they resemble the old bricks as much as possible. Seaming the wall at the construction site is another way to increase the likeness.

The production and delivery of the brick facade must be scheduled carefully. The finished product must not be stored for more than a week. Otherwise, it will start to curve, which makes the installation very difficult.

The material of the brick façade are the real fired bricks, although thinner than traditional masonry bricks. Variations in width, length and thickness may occur.

If the surface area of the slab is large and a lot of bricks are used, it may be impossible to get the bricks to stay perfectly straight. This is okay because the rustic old style is part of the brick facades. Handprint can be visual in the same way as in the work of masons.