Challenging structural design in Oslo

The award-winning DNB Bank Headquarters in Oslo counts among Lasse Rajala’s most challenging works in recent years. The imposing building was awarded in the European Steel Design Awards 2015 for its multifaceted, demanding structure and innovative implementation.

The main designer of the building, which was completed in 2012, was a famous Dutch architectural office MVRVD. Steel structures were delivered and installed by Ruukki Construction. Sweco was responsible for the structural design of the building’s steel frame.

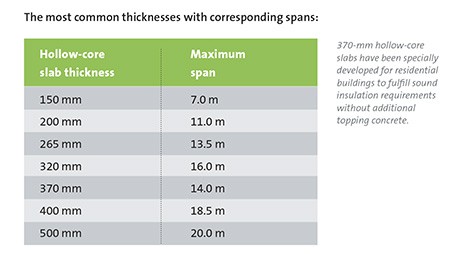

The building consists of cube-like six-by-six-meter projections from the core of the structure. Hollow core slabs are used for all intermediate floors of the 17-storey building. There are numerous suspended structures and projections connected to the glass facade in the complex ensemble.

“This makes the structural design of the building very challenging – the degree of complexity is in a class of its own,” Rajala says.

In addition to the numerous details, the building had to be designed to meet earthquake-resistance standards due to the quality of the soil. “Hollow core slabs are ideal for seismic areas.

As the own weight of the hollow core slab is much less than a corresponding solid slab, the lateral forces during seismic action will be reduced accordingly,” Rajala says.

Lasse Rajala works at Sweco Finland Ltd., specialized in the built environment and industry. Sweco operates in the fi elds of structural, industrial, environmental and municipal engineering, as well as building service systems and architecture.