Elematic’s fleet management services – manage your precast machinery fleet like a pro

Well-functioning precast machinery keeps a plant’s production rolling, so maintaining machinery and ensuring high uptime is the key in attaining continuous top performance. Visibility, uptime, productivity – and everything you need for comprehensive maintenance management and planning is available through Elematic’s fleet management.

Remote service is not a new phenomenon at Elematic. With a helpdesk launched in 2004, we were one of the first in the business to offer precast support remotely. Since then, we have developed our service offering based on customer needs and pains. A new era of digital services with Elematic’s fleet management is upon us.

The newly developed software includes applications for precast machinery monitoring, production monitoring, and maintenance planning. The focus is on real-time visibility into machine operations, preventive maintenance implementation, production data analysis, and maintenance cost control. These are crucial for enhancing productivity, minimizing unexpected downtime and quality issues, and enabling productivity improvements and quicker problem resolution.

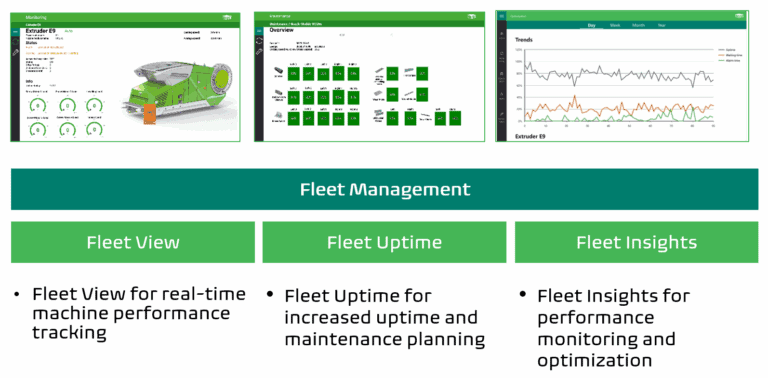

Fleet Management

Fleet view for real-time machine performance indicators

The fleet view enables monitoring the fleet performance in real-time. For example, you can view motor loads, drive torque, distance from the start, casting speed, average speed, and uptime. In addition, there are alerts, e.g. if the lubrication grease level is too low. All this essential real-time data helps to ensure all machines are operating correctly and prevent any minor issues, such as the lubrication grease level, from escalating. In other words, the fleet view enables immediate reaction to alarms.

Fleet uptime for increased uptime and maintenance planning

The fleet uptime allows changing the maintenance planning and execution strategy from calendar-based to condition-based maintenance. In this view, all the maintenance needs of the fleet are visualized: you can see the remaining lifetime of every part. This minimizes unnecessary maintenance with fact-based planning and reduces costs by optimizing the maintenance and spare part delivery schedules.

Fleet insights for data insights and performance optimization

The fleet insights let you dive deeper into the fleet performance; has the uptime gone up or down, what are the reasons behind it, and how can we improve? It is a powerful tool for improving processes by troubleshooting and fine-tuning recipes and extruder casting parameters. By analyzing the historical data, e.g. uptime, screw loads, alarms, logged events, energy consumption and casting time, it’s easier to improve equipment performance and enhance overall production efficiency. These machine KPIs can also be connected to your company’s business system.

The fleet insights assist not only you as a machine owner, but also Elematic service engineers in understanding production details and challenges.

The services are based on machine data provided via secure mobile connectivity and cloud solutions. They can be accessed from anywhere through the Internet, on mobile and desktop devices.

By embracing smart fleet management solutions, precasters can drive efficiency, reduce costs, and pave the way for a more sustainable and data-driven future in the precast business.

Let others enjoy this, too!

If you are interested, contact us for more information.

or