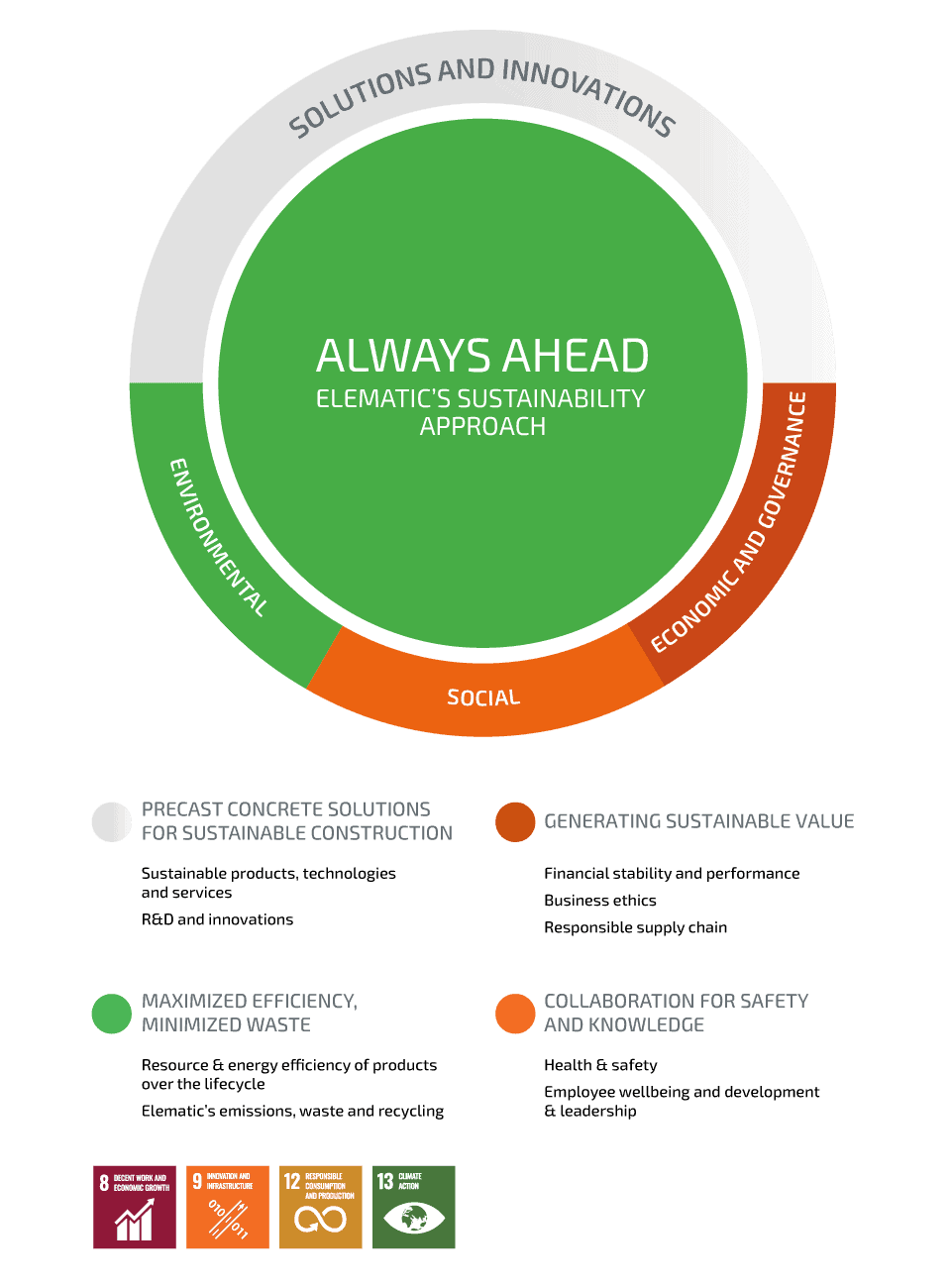

Sustainability runs through our strategy from mega trends to customer needs and our offering. Skilled and diverse Elematic people and good leadership play a central role in the sustainable progress and growth of our business.

Precast concrete solutions for sustainable construction

Precast concrete is resource-efficient, scalable, and flexible, and provides architectural freedom. It makes the whole construction process more efficient. Concrete structures have a long service life and low need for maintenance and repair, providing significant sustainable value.

Elematic delivers performance and sustainability over the entire lifetime of precast technologies and products. Examples of Elematic’s innovation and high quality include the following:

- Energy and resource-efficient production technology

- Shear compaction technology to reduce the use of cement

- Solution for recycling concrete during production

- Reusable shuttering system to reduce waste

- Services to extend product lifecycles

- Durable design to extend product lifecycles

- Solutions for water recycling in manufacturing processes