SEMI Wall

The Elematic SEMI wall precast production line offers straightforward, easy-to-learn technology to produce high quality precast products with low operational costs.

The SEMI Wall is the best choice when an annual production capacity of 70,000 – 150,000 m2 is required and the production will have little variation in product types. It can produce product types including sandwich panels, cladding panels, solid panels, solid slabs and other precast products such as stairs and beams.

As with all Elematic production lines, the SEMI Wall can be, and almost always is, customized to suit the needs of a specific factory.

Download a brochure

SEMI Wall line*

| Theoretical capacity | 280-600 m2/day (one casting) |

|---|---|

| Personnel | 10 |

| Production area | 2000 m2 |

| Land area | 20 000 m2 |

| No. of tables | 10-15 |

| Typical size of table | 3.5 x 8.0 m |

| *All figures are estimates |

The Elematic SEMI wall production line features mechanized production technology. The line needs only an area of 2000 m2 for production and it can also operate as an open-air factory. The total land area required for operation is 20 000 m2.

Tables on the SEMI Wall line are stationary, with a maximum of 15 tables. It requires 10 personnel.

TAKE A LOOK AT A 3D MODEL OF THE FACTORY CONCEPT

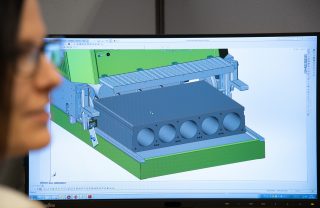

The core machine that makes this line different from other lines with a similar production capacity is the Multifunction wagon. This both compacts the concrete and tilts the tables after curing. The line’s high-quality tables have a sturdy steel construction and completely even surfaces to ensure excellent panel quality.

PROCESS DESCRIPTION

Wall panel production on the SEMI line takes place in 9 functional steps:

- Batching and mixing

- Concrete transportation

- Shuttering and furnishing

- Casting and compaction

- Curing

- Demolding

- Wall surface finishing

- Table surface cleaning and oiling

- Storing, including lifting and transferring

The production process starts with table preparation, which is carried out manually. The preparation phase includes cleaning and oiling the tables, shuttering the tables with side forms and openings, and furnishing the surface tiles etc., if required. The casting, compaction and curing take place on stationary tables, so the work is straightforward and easy to monitor. The fresh panels are stripped off the table with a lifting beam connected to an overhead crane and moved to the finishing area or directly to the storage by a transport wagon.

SAFETY

All machines on the SEMI Wall line meet EC Machine Directive requirements. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Related products and services

Benefits

-

Simplicity

Can operate as an open-air factory

-

Practical solutions

Multifunction wagon both compacts the concrete and tilts the table

Other wall lines

Precast products

Do you have questions? Contact us.

or