PRO Wall

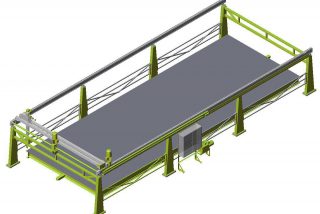

The Elematic PRO Wall precast production line consists of a circulation line and optional battery molds, tilting tables, staircase molds and beam and column molds. It can automate all key production functions.

The PRO Wall is the best choice when an annual production capacity of 170,000 – 300,000 m2 is required and production includes many different product types. It can produce a range of product types including sandwich panels, cladding panels, solid panels, solid slabs and other precast products such as stairs and beams.

As with all Elematic production lines, the PRO Wall can be, and almost always is, customized to suit the needs of a specific factory.

Download a brochure

PRO Wall line*

| Theoretical capacity | 684-1200 m2/day (one casting) |

|---|---|

| Personnel | 15-20 |

| Production area | 2800 m2 |

| Land area | 45 000 m2 |

| No. of tables | 20-30 |

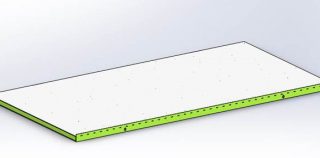

| Typical size of table | 3.8 x 9.0 m |

| *All figures are estimates |

The Elematic PRO wall production line features mechanized production technology with sophisticated machines and a medium level of automation. The line needs an area of 5 320 m2 for production and service, and the total land area required for operation is 45 000 m2.

The PRO Wall line is a circulation line where tables move along the production steps. The maximum number of tables in the PRO Wall is 30. It requires 15 – 20 personnel.

The PRO Wall minimizes concrete consumption thanks to accurate dosing by the Comcaster casting machine, and it uses floor space efficiently because the curing takes place in stacks. The Elematic PRO Line is equipped with tables that have a sturdy steel construction for high load-bearing capacities (600 kg/m2).

PROCESS DESCRIPTION

Wall panel production on the PRO line takes place in 9 functional steps:

- Batching and mixing

- Concrete transportation

- Shuttering and furnishing

- Casting and compaction

- Curing

- Demolding

- Wall surface finishing

- Table surface cleaning and oiling

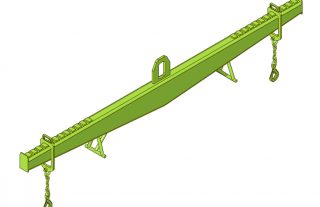

- Storing, including lifting and transferring

The process starts with table preparation. First, the table is cleaned by the brushing unit on the cleaning machine, after which an oiling unit oils the table. In the shuttering phase, the Plotter first marks the spots for the side forms, window and door openings, and other inserts, after which the side forms and window and door openings are placed manually on the spots with the FaMe magnet shuttering system. Reinforcements and other inserts are also added to the table.

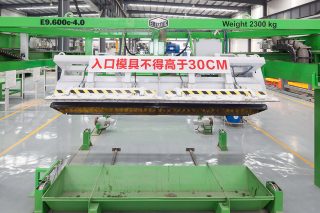

Next, the table moves to the casting machine where the concrete is cast, and at the same time, the compaction station compacts the concrete. If the precast product is insulated, the insulation is laid on top of the first cast layer, after which the second layer of concrete is cast. The table is then moved by the lifting frame to the curing stack. When curing is finished, the table is taken out with a lifting frame, the shuttering is removed manually, and the table is tilted up at the tilting station. The finished product is then transported with a transport wagon to the storage yard.

The whole process is managed and controlled with the world’s most advanced ERP system designed for precast production, the Elematic Plant Control.

SAFETY

All machines on the PRO Wall line meet EC Machine Directive requirements. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Related products and services

Benefits

-

High productivity with circulation

-

Efficient use of concrete

-

Top quality end products

Other wall lines

Precast products

Software

Do you have questions? Contact us!

or