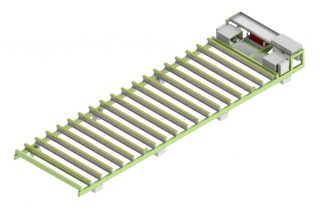

Half slab long line

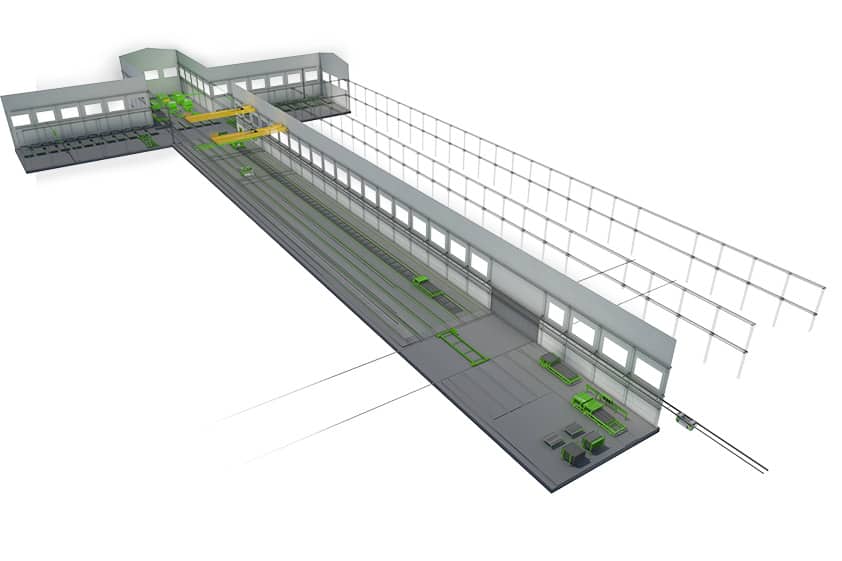

The Elematic half slab long line is a fast and advanced technology to produce non-stressed and prestressed half slabs of varying lengths and widths. The annual production capacity of the line is 1,400,000 m2.

Download a brochure

Technical specifications

| Capacity | 1 400 000 m2/a |

|---|---|

| max. 4 500 m2/day (2 castings) | |

| Production area | 5 200 m2 |

| Land area | 15 500 m2 |

| Typical casting bed size | 2.8 x 150 m |

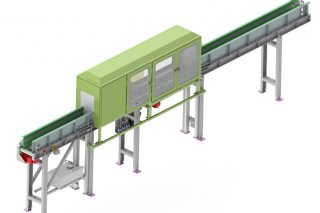

The half slab long line offers mechanized or automated work phases. The Elematic Plant Control takes care of production planning, line control and machine operations.

The service functions and material storage flows are optimized according to production needs. Reinforcements are produced just-in-time and automatically moved to the correct production station. Two side-shifters and a reinforcement wagon with a boom crane transport them efficiently. The long line also has a flexible side form stock and an efficient form handling process.

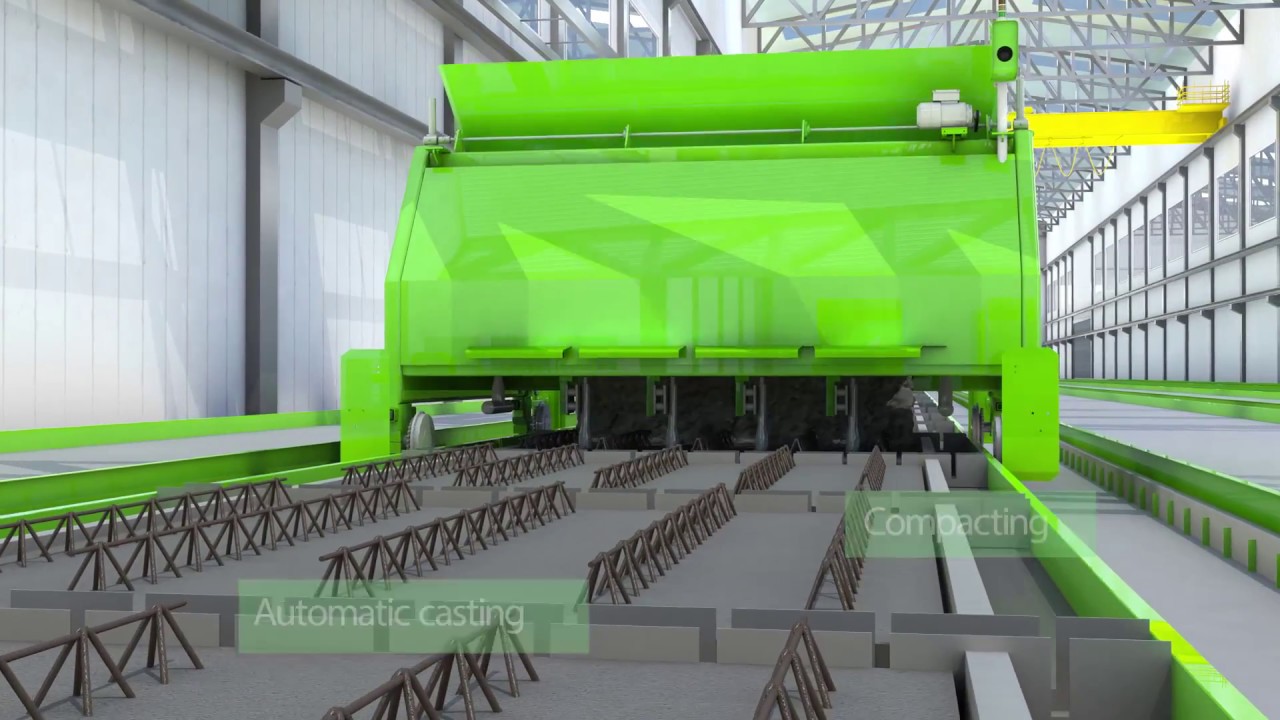

An automatically produced load list shows how many pieces of each form length are required in the process. A high-pressure washer – 400 bar – takes care of cleaning. The casting bed features strong steel foundations with heating pipes to accelerate concrete curing. The bed is totally planar, and it is equipped with a removable standard side form on each side. An automatic plotter marks slab widths, lengths and recesses on the bed. This ensures accurate dimensions and minimizes errors. In addition, the line features the option to change machines on both ends of the line, for decreased waiting times during the process.

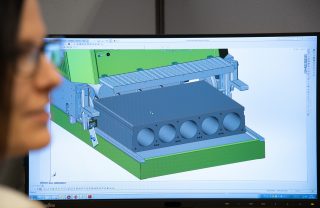

An automatic casting machine provides fast and accurate high-capacity casting with efficient compaction.

The half slab long line needs an area of 5 200 m2 for production, and the total land area required for the operation is 15 500 m2. The line includes 6 beds of 150 meters in length.

PROCESS DESCRIPTION

Precast slab production on the half slab long line takes place as follows:

- Demolding

- Bed cleaning

- Furnishing

- Reinforcing

- Concrete distribution

- Casting

- Curing

- Storing

On a long line, machinery and work teams move separately according to process needs.

PERSONNEL REQUIRED*

The factory is designed to work in 3 shifts.

There are 11, 13 and 10 people per shift in the production hall, for a total of 34 people.

Reinforcement shop: 8 + 8 + 6

Product storage: 2+2+2

Maintenance: 2+1+1

Quality control and concrete laboratory: 1 + 1 +1

Batching and mixing plant: 1+1+1

In total, there are 26 people in the morning shift + 27 people in the evening shift + 22 on the night shift = 75 people.

*White collar, maintenance people, special tasks, etc. not included. The number of personnel needed to operate the line is strictly a non-binding indicative estimate.

SAFETY

All machines on the half slab long line Floor line meet EC Machine Directive requirements. The machinery is designed to keep noise levels low and enhance safety. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Related products and services

Benefits

-

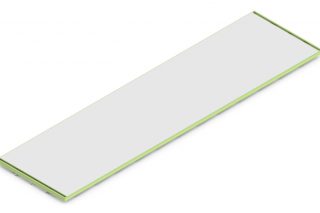

Flexible production

The line can produce both non-stressed and prestressed half slabs in varying lengths and widths.

-

High productivity

High productivity thanks to fast production space and high space utilization.

-

Excellent slab quality

Excellent slab quality with efficient vibration, bed heating and maturity control

Other floor lines

Precast products

Do you have questions? Contact us!

or